Sand washing can remove impurities covering the surface of the sand, and at the same time destroy the water vapor layer of the coated sand to facilitate dehydration and play a role in efficient sand washing. Sand washing equipment is suitable for sand, coal, pebbles, etc.

Washing equipment includes LSX Screw Sand Washing Machine, DS Series Multi-Function Sand Washer, LZ Sand Washing and Recycling Machine concentrator. The spiral sand washing machine has a washing height, reasonable structure, large output, and less sand loss during the sand washing process, especially the transmission parts are separated from water and sand.

Dewatering is the process of removing moisture from a mineral processing product. The choice of the dewatering method should be based on the nature of the material (grain size, specific gravity, magnetic properties, etc.) and the moisture of the product before and after dehydration.

The process of removing moisture from mineral processing products. Mineral processing products usually contain a large amount of water, such as flotation concentrate ore generally contains 70-85% water. The dewatering of the concentrate can meet the requirements of the smelting and other processing departments; reduce transportation difficulties and costs; return the used water to the concentrator for reuse, which can save water consumption. Sometimes in order to meet the requirements of the next sorting operation, the intermediate product of the beneficiation needs to be dehydrated.

Dewatering equipment includes, Ts Dewatering Screen, Trommel Screen.

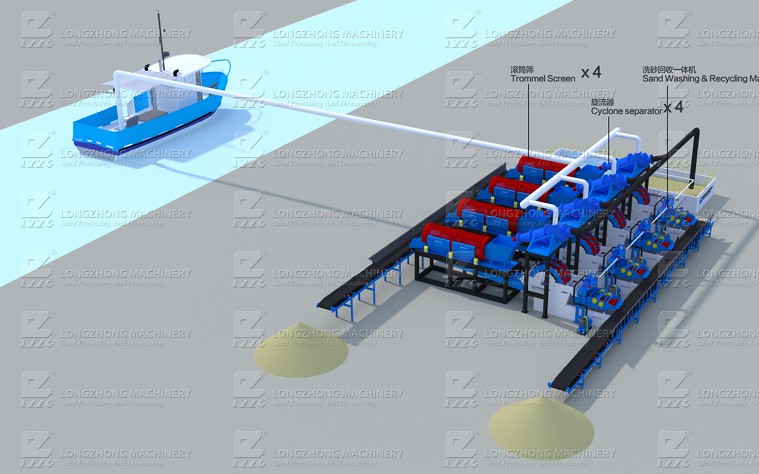

Equipment for extracting sand and gravel from river silt

Modular Construction Waste Processing Plant

Jigging machines for tungsten tin and gold ore dressing

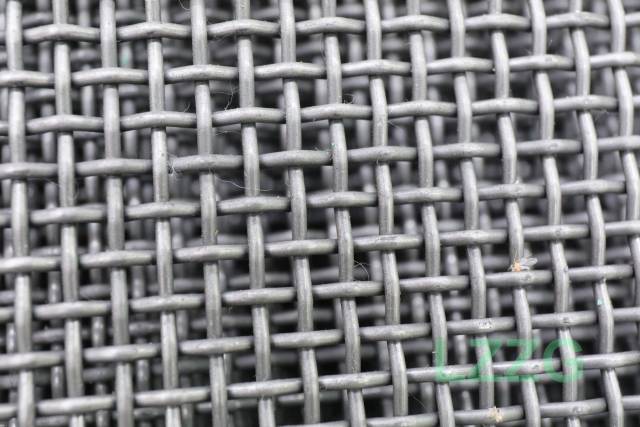

Mining wear-resistant manganese steel screen woven ore classification screen