Conpany Intrduction

Polish Construction and Mining Machinery Exhibition Exhibition Name: Warsaw Construction Expo Exhibition Hall: PTAK WARSAW EXPO Exhibition Hall Address: Aleja Katowicka 62, 05-830 Nadarzyn, Poland Time: April 6, 2025 Booth Number: D4.22

More +

Construction waste concrete blocks, after crushing, can replace the coarse aggregate needed for concrete preparation. They can also be used directly in building foundation reinforcement, road construction, airport runway sub-bases, indoor stadium flooring, and other applications.…

More +

September 17-19, 2025 Almaty, Kazakhstan Hall 8, Booth 8-514 Miningmetals & Kazcomak is the largest and most influential exhibition for engineering and mining machinery in Kazakhstan and Central Asia. Organized by the ICA Group, the…

More +

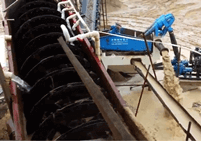

Dewatering screen for coal washing plant ready for shipment

Water-washed coal dewatering linear screen Coal slime de-medium dewatering screen Dewatering screen, the main function is dewatering, desliming, de-mediuming, can be used for water-washed sand in sand and gravel plant, coal slime recovery in coal preparation…01/10/2025

Learn More>

Uses of sea sand

Sea sand refers to sand and gravel in the ocean, which is formed by the scouring, rolling, collision and grinding of sea water. As an important marine mineral, sea sand has a wide range of uses.…06/26/2024

Learn More>

Indonesia 25,000 ton annual high-purity quartz sand project

The purity of the quartz sand produced by the company can reach more than 99.6%, which can be used as raw materials for ultra-white glass, photovoltaic glass. According to the design plan, the proposed project is…06/17/2024

Learn More>

Indonesia laterite nickel ore deep cone concentrator

The ore preparation process of hydrosmelting is mainly ore washing and chromium removal. The raw ore is mainly low-grade limonite or mixed ore mixed with residual ore, which has the characteristics of high moisture content, high…04/23/2024

Learn More>

Conpany Intrduction

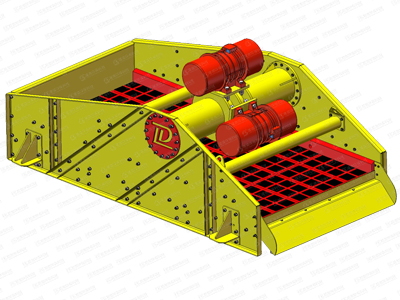

Ts Dewatering Screen

GP tailings dewatering screen

LZ sand washing & recycling machine

XS sand washing & dewatering machine

LSX screw sand washing machine

LZ sand recycling System

Y series vibrating screen

LSX screw sand washing machine

No.6 fine sand recycle system

Slurry Treatment System

LZ sand washing & recycling machine

LZ sand recycling System

Y series vibrating screen

Ts dewatering screen

GP tailings dewatering screen

After the river sand is mined, it is inevitably doped with impurities such as soil and particles, and the river sand is of low quality. A sand washing plant is needed to achieve simple river sand…

More >

According to the "Cambodian Minerals Law", mining in Cambodia is divided into individual mining and industrial mining. Individual mining means that the local residents in the mining area carry out manual mining on their own land,…

More >

The screening and washing machine is used for washing, dewatering and grading of gravel aggregates, piling mud and silica sand. The machine has a compact structure, small footprint, can be quickly installed and moved, and can…

More >

The single-layer vibrating screen can screen two different grades of materials when screening materials. The assembly type and welding type of the high-frequency linear vibrating screen have certain differences in product installation and components. The assembly…

More >

30th Central Asia International Mining Exploration and Mining Equipment Exhibition

September 17-19, 2025 Almaty, Kazakhstan Hall 8, Booth 8-514 Miningmetals & Kazcomak is the largest and most influential exhibition for engineering and mining machinery in Kazakhstan and Central Asia. Organized by the ICA Group, the…08/22/2025

Learn More>

Meet LZZG On MBAM OneBuild 2025

For over a decade, MBAM OneBuild has established itself as Malaysia’s premier platform for construction and infrastructure technology, bringing together global industry leaders, renowned brands, and thousands of professionals each year. This flagship event not only…07/31/2025

Learn More>

The 2nd International Exhibition for Construction and Building Materials

LZZG Booth No.: Hall 2 B27-1 Saudi Arabia is one of the well-known construction machinery and mining exhibitions in Saudi Arabia. There is a building materials theme at the same time. The organizer is the famous…04/23/2025

Learn More>

2025 Moscow International Mining Machinery Exhibition

Exhibition Information Exhibition Name: 2025 Moscow International Mining Machinery Exhibition Exhibition Time: April 5, 2025, 23-25 Exhibition Location: Moscow O CROCUS-EXPO Exhibition Center Exhibition Cycle: Once a year II. Exhibition Introduction MiningWorld Russia 2025 is the…03/19/2025

Learn More>

Coal Sill screen Machine Automatic Vibration Separation Screen

Water-Saving Sand Washing and Sludge Treatment Complete Equipment

How Efficient are Hydrocyclones in Metal Ore Beneficiation?

Advantages of Hydrocyclones Mineral Separator in Lead-Zinc Ore Beneficiation