Rotary trommel separator machine for sale

What is a trommel machine?

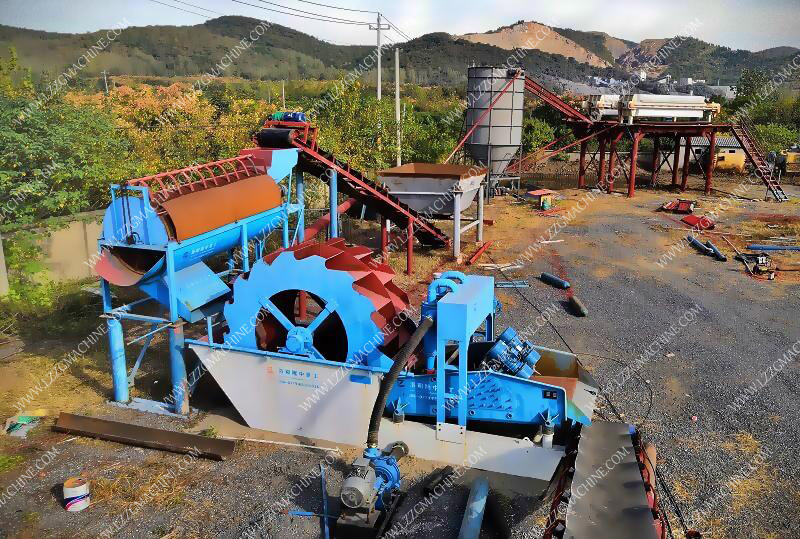

The trommel screen is a mechanical screening device used to separate materials like soil, mulch, and sand, ore, coal, gravel, mainly in the mineral and solid-waste processing industries, also called rotary screen or drum screen. We are a manufacturer, all products sale at factory price. The products have been sold to Thailand, Indonesia, South Africa, Australia, Europe, etc.

It’s designed to minimize setup time and be easy and convenient to service. We have perfected the ability to size and customize drum screens with different materials to suit the application, such as the updated product compact sand washer.

Price USD $6000~$10000

Working principle of Trommel Screen

The trommel separator is tilted on the rack. The motor is driven by the reducer to rotate the drum unit around its axis. After the material enters the drum device, due to the tilting and rotation of the drum device, the material on the screen surface is flipped and rolled so that the qualified material (the product under the screen) is discharged through the discharge port at the bottom of the drum screen, and the unqualified material(the product on the screen) is discharged through the discharge port at the tail.

Screening of wet and dry materials

For dry material, trommel screen is turned over to make the material and the screen effectively contact, and the dry material can be quickly screened.

For wet material, the machine drives the wet material to roll so that the materials are thoroughly mixed with the air. Making them drier, facilitating screening and reducing the blockage of the screen.

Application

The rotary screen is sieved by gravity centrifugal force. This trommel machine can be used as a wood chip screener, soil separator machine. wood chip screenerMaterial suitable for the drum screen:

- Stone yard for grading of large and small stones, and separation of soil and stone powder.

- Coal industry for the separation of lump coal and pulverized coal and coal washing (part of coal washing machinery)

- Grading and separating powdery materials

- For urban waste sorting

- Building materials

- Coal preparation

- fertilizer

- Topsoil

- Glass

Product Features

- The screen hole is not easy to block.

- Running smoothly and the noise is low.

- The structure is simple and the maintenance is convenient.

- The rotary trommel screen can be closed, and easy to collect dust.

- Various plate and mesh sizes

- Screen drums made to customer specifications.

Technical parameters

| Model | Feed size (mm) | Capacity (t/h) | Cylinder size (mm) | Cylinder inclination (o) | Power (kw) | Dimensions (mm) |

| YGT1040 | ≤50 | 30-60 | 1000X4000 | 6 | 3kw | 5500X1460X2340 |

| YGT1240 | ≤50 | 30-100 | 1200X4000 | 6 | 5.5kw | 5500X1680X2480 |

| YGT1560 | ≤50 | 30-150 | 1500X6000 | 6 | 11kw | 6800X2100X4400 |

| YGT1860 | ≤50 | 30-200 | 1800X6000 | 6 | 15kw | 8490X2400X4680 |

| YGT2160 | ≤50 | 30-200 | 2100X6000 | 6 | 18.5kw | 8490X2760X5000 |

| YGT2460 | ≤100 | 30-250 | 2400X6000 | 6 | 18.5kw | 8490X3020X5200 |

| WGT1560 | ≤100 | 30-150 | 1500X6000 | 5-10 | 7.5kw | 6800X2100X4400 |

| WGT1860 | ≤100 | 30-200 | 1800X6000 | 5-10 | 11kw | 8490X2400X4680 |

| WGT2160 | ≤100 | 30-250 | 2100X6000 | 5-10 | 15kw | 8490X2760X5000 |

| WGT2480 | ≤100 | 30-300 | 2400X8000 | 5-10 | 22kw | 8700X2860X5700 |

| WGT3080 | ≤100 | 30-400 | 3000X8000 | 5-10 | 37kw | 8800X3660X5800 |