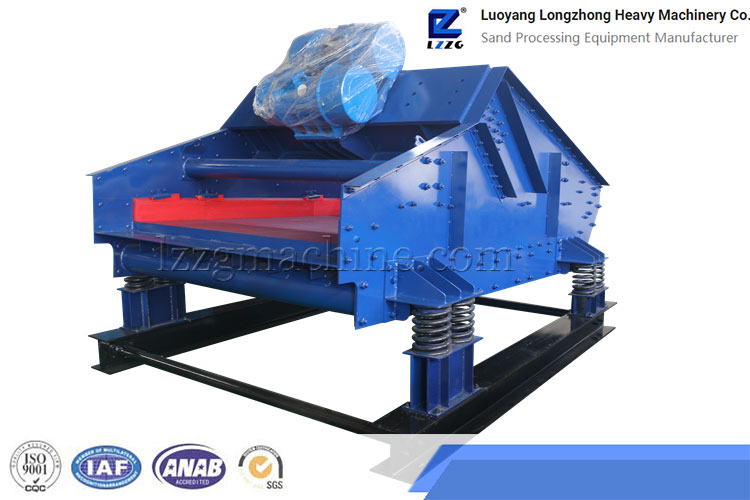

Dewatering Screen For Coal, Mud, Sand Drying

High dewatering ratio vibrating screen

TS series dewatering screen output low moisture content materials like sand, coal, mud and tailings, hot sale in the market. It use wear-resistant polyurethane sieve panel , not easily blocked in screening. When processing mineral pulp such as coal, mud or dirt mixed water, steel mesh is easily blocked and adjusting its mesh size will highly reduce its capacity.

It is important for owner to get dry sand directly after washing process, here comes our new type high G-force vibrating screen. Also we use high-quality PU screen as its sieve, one side you can get fine sand and also dry sand at the same time.

Application: Mainly used in mining, construction as sand dewatering equipment. It also can be applied to dewatering of coal, sintered ore, ore pulp. It has simple structure and easy to maintenance, hot sale in China, Vietnam, Indonesia.

Capacity 10~100ton/hour

Working principle

Dewatering screen adopts dual-motor self-synchronization technology. The motors coordinate with universal eccentric and adjustable amplitude vibrator. When the two motors start to work, the vibrators move reversely at the same time. The centrifugal forces is generated by the eccentric blocks will superpose themselves and form a single direction vibration. The high frequency vibration drives the screen move back and forth in line repeatedly. So the sand can be dehydrated and filtered.

Water Remove Capacity

The incoming material enters the sieve inlet, first remove 1/3 of the water at the pre-dewatering sieve plate, and after entering the junction of the flat sieve plate and the inclined sieve plate, the material gradually accumulates. The water that fails to pass through the sieve plate is intense It is gradually removed under movement, and the material particles form a tight filter layer in the state of high frequency and low amplitude, and gradually vibrate to the discharge port, with a moisture content of about 15%.

Product Features

1. Advanced structure, light weight, high dehydrating ratio with new type vibrating motors.

2. Simple structure, easy maintenance.

3. Cross beam and screen body connect with high strength bolts, no welding and easy to remove and maintenance.

4. Polyurethane screen (PU) high screening ratio, big capacity,long service life and no blocking.

5. Widely used, less replacement parts.

Technical parameters

| Model | Feed size | Capacity | Screen Panel | Screen Area | Power | Overall Size |

| mm | t/h | mm | m² | kw | mm | |

| TS0918 | ≤10 | 10-20 | 900X1800 | 1.62 | 0.75X2 | 1890X1290X1080 |

| TS1224 | ≤10 | 20-40 | 1200X2400 | 2.88 | 2.2X2 | 2480X1590X1430 |

| TS1230 | ≤10 | 20-40 | 1200X3000 | 3.6 | 2.2X2 | 3080X1590X1500 |

| TS1530 | ≤10 | 30-60 | 1500X3000 | 4.5 | 3.0X2 | 3080X1890X1440 |

| TS1536 | ≤10 | 30-60 | 1500X3600 | 5.4 | 3.0X2 | 3680X1890X1450 |

| TS1842 | ≤10 | 60-80 | 1800X4200 | 7.56 | 5.5X2 | 4370X2420X2100 |