Methods for efficient ore washing

According to the characteristics of different ores, choosing suitable washing equipment can improve the washing efficiency. Hydraulic ore washing screen The ore washing method using a water gun to wash…

published date: 02-23-2019

Manganese ore washing plant is professional equipment used for washing. The washing can remove or reduce harmful impurities, enrich the useful components in the minerals, and avoid the muddy materials in the mud mineral raw materials blocking the crushing and screening equipment. Therefore, low-grade ore can be economically utilized.

Washing is the action of water scouring and mechanical agitation to break up and disperse the clay, separate the clay from the ore and form a suspended slurry. Therefore, it is the two operations of dissociating and separating the ore components. the process of. Manganese ore, iron ore, limestone, especially manganese ore deposits that are weathered, leached and transported, are essential for washing.

Trommel Screen

The washing screen is formed by milling or weaving into a cylindrical screen, and is placed on the bracket and driven by a roller, and the inclination angle is 5° to 7°. In some cases, in order to obtain a finer grain product, Concentric cylinder screens of two or three cylinders are sometimes used.

In order to strengthen the mechanical action on the material to be washed and increase the residence time in the cylinder, sometimes steel bars, angle irons, spiral plates and transverse annular plates are installed. In order to facilitate the flushing of materials, a pressure spray pipe is installed in the cylinder.

Screw ore washing machine

The Screw ore washing machine consists of an inclined tank and one or two agitated shafts and transmissions with blades. As the shaft rotates, it collects the ore along the long axis of the washer and moves them up the slope of the tank to the discharge port. The washing efficiency of the tank washing machine depends on the inclination angle of the groove, the inclination angle of the spiral blade, the number of rotations of the spiral blade, and the amount of water supplied.

The manganese ore washing plant produced by our company has the following characteristics:

1. Simple structure, stable operation, and high washing efficiency.

2. The fine ore loss is less, the wearing parts are less, and the maintenance is convenient.

3. The impeller drive bearing device of the device is isolated from water and water-receiving materials, which greatly avoids the occurrence of damage caused by water immersion, sand and pollutants, and improves the service life.

At present, LZZG’s manganese ore washing equipment has been widely used in steel, metallurgy, chemical, building materials, mining, coal, smelting and other industries, making the efficiency of the beneficiation production line of customers in India, Vietnam, Indonesia, Australia, South Africa and other regions greatly improved. .

According to the characteristics of different ores, choosing suitable washing equipment can improve the washing efficiency. Hydraulic ore washing screen The ore washing method using a water gun to wash…

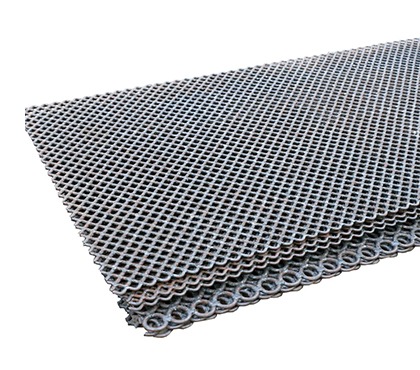

Features of wear-resistant screen. The screen is woven by high manganese steel wire, with high mesh precision, complies with ISO14315 international standard, good mesh surface flatness, good wear resistance and…

Iron ore washing instruction Ore washing is the gravity dressing process used to treat ore that is cemented with clay or contains much mud. Mainly the process of separating materials…

Stone washing machine, also called sand washing machine (or gravel washing machine), is used for desliming and screening of sand and gravel at construction sites and sand and gravel plants.…