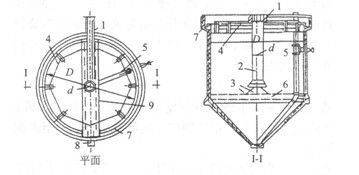

Rake thickener

The thickener is a solid-liquid separation equipment based on gravity sedimentation. After the slurry is mixed with the flocculant, it enters the thickener through the central cylinder. The guide plate…

published date: 08-07-2019

Sludge thickener utilizes the relative density difference between solid particles and water in the sludge to achieve sludge thickener. The sludge from the primary sedimentation tank can be directly concentrated into the concentration tank for concentration. The water content can generally be concentrated from 95% to 97% to 90% to 92%. The excess sludge is generally not suitable for gravity concentration alone. If gravity is used for concentration, the water content can be reduced from 99.2% to 99.6% to 97% to 98%. For a sewage treatment plant with a primary sedimentation tank and a secondary sedimentation tank, the two sludges can be mixed and gravity concentrated.

Sludge concentration is an important process for the disposal of solid waste. It minimizes the waste of water and allows the biosolids to be reprocessed so that they can be safely recycled back to the waterway. Using the right product and municipal wastewater treatment solutions is critical, and our engineers will provide your company with a secure process.

Failure to thicken the sludge in wastewater treatment means that you may waste water unnecessarily. In addition, solids may re-enter the system and cause pollution. If the sludge is not properly removed, thickening can cause problems in the tissue because it can cause health and environmental hazards.

(1) Solid flux (or sludge solids load): The amount of dry solids passing through the surface of the unit sludge thickening tank per unit time, in units of kg/(m2·d). When the initial sedimentation sludge is concentrated, the sludge solid load can take a larger value; when the excess sludge is concentrated, a smaller value should be used.

(2) Hydraulic load: The supernatant overflow flow rate per unit time through the surface area of the unit concentration tank, the unit is m3/(m2·h) or m3/(m2·d). The maximum hydraulic load of the primary sludge can be 1.2~1.6m3/(m2·h); the excess sludge is 0.2~0.4m3/(m2·h). After calculating the area of the gravity thickener tank according to the solid load, it should be compared with the area calculated by the hydraulic load and take a larger value.

(3) Concentration time: generally not less than 12h.

(4) Effective water depth of the thickener tank: generally 4m.

(5) Sludge chamber volume and sludge discharge time: It should be determined according to the sludge discharge method and the time interval between two sludge discharges. When using regular mud discharge, the interval between two sludge discharges can generally be 8 hours.

(6) Moisture content of sludge after concentration: When the moisture content of sludge from the secondary sedimentation tank into the sludge gravity concentration tank is 99.2%~99.6%, the moisture content of the sludge after concentration can reach 97%~98%.

(7) When the grid concentrator is used, the outer edge line speed should generally be 1~2m/min, and the slope of the bottom of the pool to the mud bucket should not be less than 0.05.

(8) When using the biological phosphorus removal process for wastewater treatment, gravity concentration should not be used.

(9) Concentrated grid bars shall be provided on the gravity concentrating tank scraper.

(10) The sludge thickener tank generally has a device for removing scum.

Considering the increasingly high environmental requirements of the wastewater treatment plant, attention should be paid to the secondary pollution control of the concentration tank when designing the concentration tank. The sludge concentration tanks generally emit odor, and new sewage plants should consider taking deodorant or deodorization measures. The rational design and operation of a continuous gravity thickener tank depends on the mastery of the sludge settling characteristics. The sedimentation characteristics of the sludge are closely related to the solid concentration, nature and source.

The thickener is a solid-liquid separation equipment based on gravity sedimentation. After the slurry is mixed with the flocculant, it enters the thickener through the central cylinder. The guide plate…

Tailings are one of the products of sorting operations in beneficiation, and the part with the lowest content of useful target components is called tailings. Under the current technical and…

LZZG thickener tank has high processing capacity, the maximum processing capacity of a single unit can handle 200m³ / h, high solid concentration at the bottom of the effluent, low…

The high-efficiency deep cone concentrator is a new product in the solid-liquid separation process. Due to low investment, small floor space, high efficiency, the quality of the underflow concentration and…