Sand and stone are indispensable raw materials in building decoration and construction. However, with the economic development in recent years, the increasing demand for sand and gravel, the massive exploitation of inland sand mines, and the protection of country’s inland river environment, the demand for sand mines has become increasingly tight.

We all know that coastal areas are rich in sea sand. Although sea sand is clean, due to its high salinity and certain corrosive. It is easy to cause corrosion of chloride ions and pose potential safety hazards for construction projects, and cause serious problems in project quality. So the State prohibits to use of sea sand that has not been desalinated as a construction material. So it can only be used for foundation backfill , etc, cannot be used for concrete or mortar. However, due to the current shortage and high price of river sand, so many people are still staring at sea sand. Therefore, in order to make full use of sea sand, it is necessary to remove the corrosive elements such as chlorine and alkali through fresh water, and to clean and dry the sea sand with fresh water. This has become a new technical issue.

So sea sand cleaning is mainly divided into two important steps:

1. To screen out impurities such as mica, light substances, and organics firstly,

2. The most important is to wash away sulfides and sulfates to clean and desalinate sea sand.

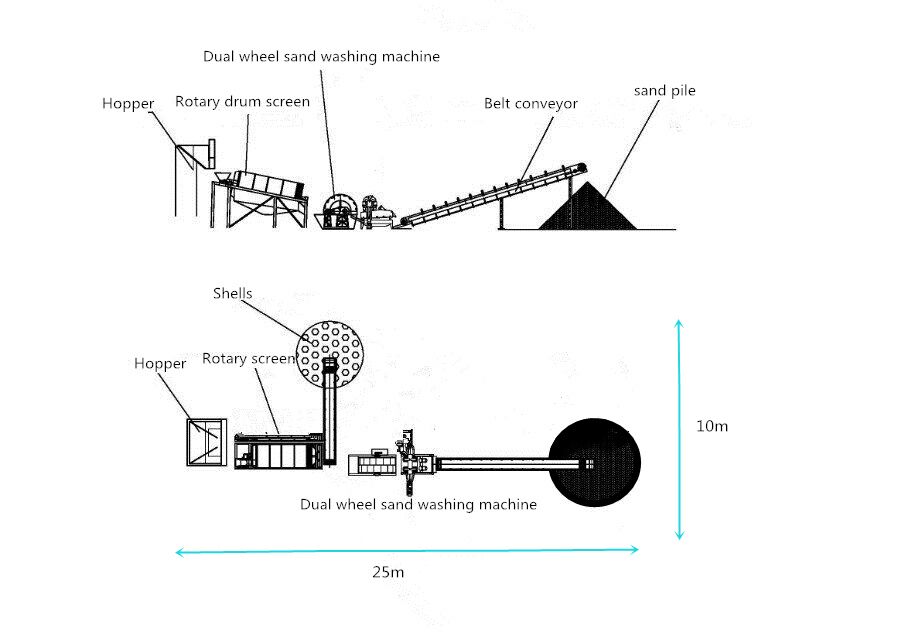

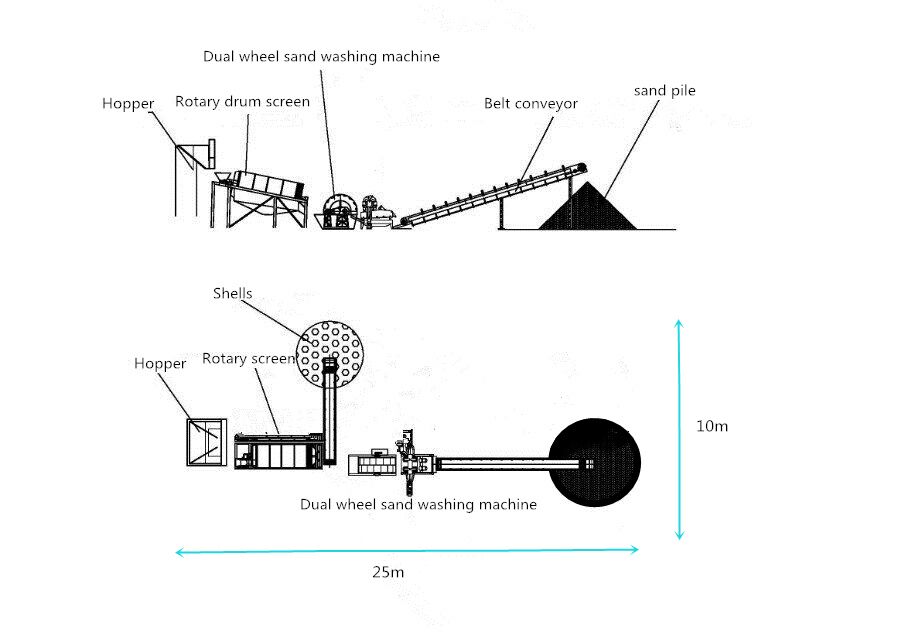

A simple sea sand washing plant as following

1.Hopper: for feeding raw materials

2.Rotary drum screen: for screening out impurities such as mica, light substances, and organics

3.Dual wheel sand washing machine: for washing away sulfides and sulfates to clean and desalinate sea sand.

4.The final products onto belt conveyor from sand washing machine to form stock piles.