Gravity Thickener Tank for Sludge Thickening

High-efficiency gravity thickener instruction

The deep cone sludge thickener is based on the traditional vertical flow sedimentation tank. The structure of the internal feed cylinder is improved, the efficiency of sedimentation is greatly improved, the plane of the sludge thickening tank body is circular, and the suspended solids settle under gravity.

In the bottom of the tank, the clarified water is discharged from the overflow weir around the upper end of the tank. The overflow port is provided with a scum filter device and a baffle to ensure the effluent water quality, the underflow concentration is up to 70%, and the treatment capacity is 3-8 times higher than that of the conventional concentrator.

Capacity 50t ~ 300t per hour

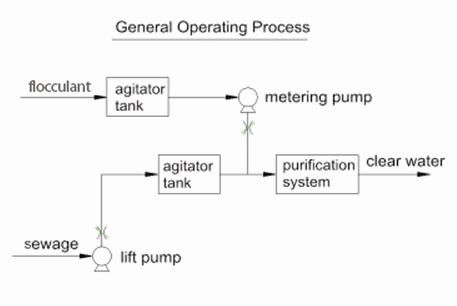

Working principle

The sludge thickening tank is based on gravity and sedimentation which makes solid-liquid separate from each other. The concentration of pulp waste water could be enhanced from 2%~ 15% to 60% ~ 70% by the machine, the clear water is overflow from the upper part of the thickener , so as to achieve the purpose of sewage purification and solid-liquid separation.

Product Features

- Automatic cleaning, automatic discharge slurry, solve manual operation

- Adopting the working principle of suspension filtration, media adsorption and settling, no purification membrane, no wearing parts

- Made of qualified carbon steel (or stainless steel, epoxy glass fiber reinforced plastic, etc.), with good strength and corrosion resistance

- Low flocculant using cost, big capacity, high efficiency, stable performance

- Small volume, small floor space, easy installation

- Service life is 10-15 years, low investment, remarkable economic benefit.

- The purified water can totally reach to national standard of discharge and can be recycled.

Technical parameters

| Model | Capacity (t/h) | Height (mm) | Volume (m³) | Weight (kg) | Overall Size (mm) |

| S-3040 | <50 | 4000 | 35 | 7800 | 3600*3600*8860 |

| S-3060 | 50-100 | 6000 | 50 | 9000 | 3600*3600*10860 |

| S-6030 | 100-150 | 3000 | 100 | 11000 | 6600*6600*9400 |

| S-6040 | 150-200 | 4000 | 130 | 14000 | 6600*6600*10400 |

| S-6050 | 200-250 | 5000 | 160 | 17000 | 6600*6600*11400 |