Recycle wastewater in sand washing plant to save water

In the clay and sand mining industry, the discharge coefficient of sand and gravel production: 2.0 tons/ton of sand washing wastewater, and the production scale is 150 tons of sand/d.…

published date: 12-21-2018

Sand washing plant with wastewater purification system

1. Seriously implement regulations, norms, and standards on environmental protection.

2. According to the sewage water quality and treatment requirements, choose a reasonable treatment process route, require the treatment technology to be suitable and reliable, and handle the effluent water quality to meet environmental protection requirements. The operation is stable and the investment is reduced while meeting the processing requirements.

3, equipment selection should consider performance and price factors, require high efficiency and energy saving, low noise, reliable operation, easy maintenance and management, and make full use of the original facilities and equipment.

The equipment includes sand making machine, sand washing and recycling machine, waste water purifying system.

Reliable filter press, Making Dry filter cake

(1) Project name: 150t/h of sewage from sand washing plant Environmental pollution control project (washing wastewater)

(2) 150 tons / h * 10 hours

(3) Nature of the project: old and old transformation

(4) Working time: 10 hours working system, annual production time is based on 300 days

(5) Pollution control project: washing sand production wastewater and sludge

Treatment scale: 1500m3/d/10h*0.9 consumption rate of sand washing wastewater, according to 4% sludge, 54 m3/d

The sand washing plant mainly produces primary products for construction. The raw water washing sand production line with a daily production capacity of 150 tons is used for crushing, sieving and washing processing of building water washing sand products.

The main environmental pollution problem in the production process of the project is the washing of sludge and domestic sewage from sandstone and silicestone. According to the requirements of relevant laws and regulations, the sand washing wastewater and domestic sewage must be discharged or recycled after treatment. The washing sludge should be disposed of properly, and the tailings can be used as a good paving gravel for export.

The material enters the sand making machine from the feeding hopper, and is subjected to two or even multiple chances of impact, friction and grinding and crushing in the vortex breaking chamber. The broken material is discharged from the lower discharge port. The sand and gravel are processed by the crusher and the sand making machine to become coarse sand.

The sand head is immersed in this pool, and the spiral is driven by electric motor through reducer rotating continuously. The fresh water is feeded from Porous plate at bottom of sediment pool, and the washed sand is discharged on the top side and delivered by belt conveyor.

Dehydrating screen adopts dual-motor self-synchronization technology. The motors coordinate with universal eccentric and adjustable amplitude vibrator. When the two motors start to work, the vibrators move reversely at the same time. The centrifugal forces are generated by the eccentric blocks will superpose The high-frequency vibration drives the screen to move back and forth in line repeatedly. So the sand can be dehydrated and filtered.

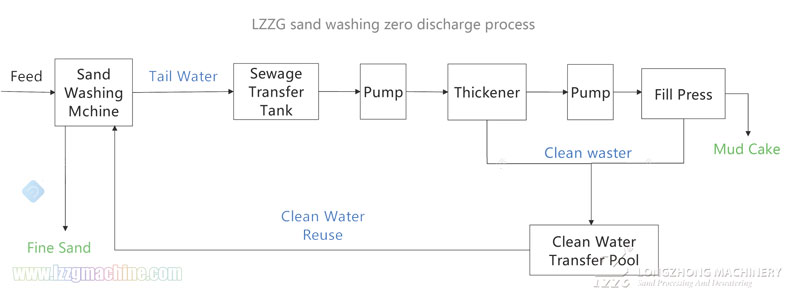

Deep cone thickener is a machine that based on gravity and sedimentation which makes solid-liquid separate from each other. The concentration of pulp wastewater could be enhanced from 2%~ 15% to 60% ~ 70% by the machine, the clear water Is overflow from the upper part of the thickener, so as to achieve the purpose of sewage purification and solid-liquid separation.

After the above steps, the amount of sediment contained in the sewage is greatly reduced, reaching the environmental emission standards.

The LZZG sand washing wastewater purification system occupies a small area, has little investment, and has a large output, which brings huge profits to customers. The products have been exported to Vietnam, Thailand, Malaysia, and Indonesia.

In the clay and sand mining industry, the discharge coefficient of sand and gravel production: 2.0 tons/ton of sand washing wastewater, and the production scale is 150 tons of sand/d.…

LZZG can reasonably configure a complete set of sand and gravel washing equipment for customers, including rock crushing and sand washing equipment, sewage sedimentation equipment. The sand washing plant has…

According to the "Cambodian Minerals Law", mining in Cambodia is divided into individual mining and industrial mining. Individual mining means that the local residents in the mining area carry out…

The YD series mobile portable sand washing plant has multifunction of washing and dewatering, screening. High cleanliness and strong machine maneuverability. It can quickly reach the construction site and can…