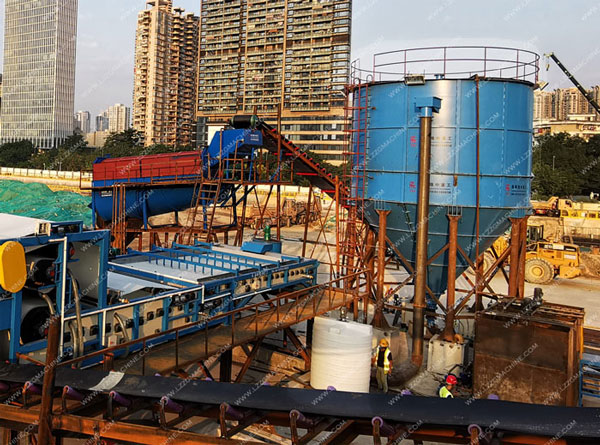

Belt filter press for sludge dewatering

what is the belt filter press

The belt filter press is widely used in urban sewage treatment, chemical, oil refining, metallurgy, paper making, leather, food, coal washing, printing and dyeing, and other sludge dewatering. The machine runs continuously, with a high degree of automation, energy saving, high efficiency, and maintenance. Convenient, it is the ideal equipment for sludge dewatering.

Working principle

The sewage enters the sedimentation tank through the mud pump, and the metering pump adds the medicament to the sedimentation tank. The sewage is quickly precipitated by the action of the medicament, and the mud pump pumps the precipitated mud to the belt filter press.

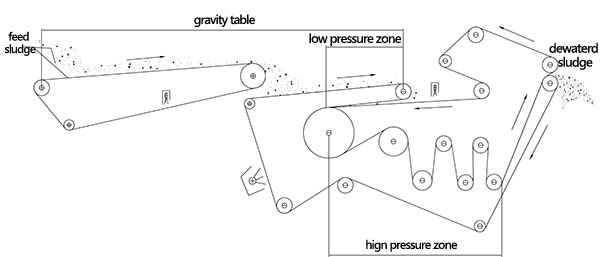

After the sludge is added with a coagulant, it is thoroughly mixed in the sludge mixer and then flows into the gravity dewatering section. Under the action of gravity, a large amount of free water in the sludge flows out from the gap of the filter belt and enters the water collection tank. Medium, and then guided by the wedge pre-pressing section, the sludge is gradually leveled and subjected to slight extrusion to further dewater, and then enters the S-type multi-stick pressing section, and the sludge is sandwiched between the upper and lower filter cloths. Rollers of different diameters are repeatedly pressed, which causes shearing of the sludge, promotes further dewatering of the sludge, forms a mud cake, and finally scrapes off the mud cake by a scraper, and the upper and lower filter belts are washed and reused.

Product Features

The belt filter press has a compact structure, convenient operation, and management, large processing capacity, low moisture content of the filter cake and good effect. Compared with the same type of equipment, it has the following characteristics:

1. The first gravity dewatering section is inclined so that the sludge is as high as 1700 mm from the ground, which increases the height of the sludge in the gravity dewatering section and improves the gravity dewatering capacity.

2. The gravity dewatering section is long, and the total length of the first and second gravity dewatering sections is more than 5 m so that the sludge is sufficiently dehydrated before the pressing to lose fluidity. At the same time, the gravity dewatering section is also provided with a special mechanism such as reversal, and the sludge cake has the lowest water content through the action of “wedge” shape and “S” shape pressing.

3. The first dewatering roller adopts the “T” type draining tank so that a large amount of water after pressing is quickly discharged, thereby improving the dewatering effect.

4, the filter belt deviation and other automatic control devices, filter belt tension and filter belt movement speed can be freely adjusted, easy to operate and manage.

5. Low noise and no vibration.

6, the amount of chemical drugs is small

The structure of the belt filter press

Technical parameters

| Model | Feed concentration (%) | Filter area (m²) | Power (kw) | Capacity (t/h) | Weight (kg) | Dimension (mm) |

| DY1000 | 30-40 | 15.35 | 17.5 | 3-5 | 4000 | 6000*1700*2000 |

| DY1500 | 30-40 | 20.55 | 20 | 5-7 | 5200 | 8200*2200*1850 |

| DY2000 | 30-40 | 24.4 | 32.8 | 6-9 | 6100 | 9300*2700*1850 |

| DY2500 | 30-40 | 34.5 | 34.8 | 9-13 | 10600 | 10320*3200*2300 |

| DY3000 | 30-40 | 44.7 | 39.3 | 15-20 | 14800 | 14300*3700*2500 |

| DY3500 | 30-40 | 54 | 39.3 | 18-25 | 17400 | 14300*4300*2700 |

Mud cake discharged from filter press

Mud cake discharged from filter press