Artificial sand mobile sand washing machine price

River pebbles are commonly used raw materials for sand making. With the gradual prosperity of the sand and gravel industry in recent years, the performance advantages of sand making equipment…

published date: 12-12-2019

A large amount of sewage will be generated during the operation of the sand washing plant. The traditional methods are sludge landfill, sludge agriculture and sludge incineration. After the landfill of sludge will cause certain environmental problems. In order to make the wastewater treatment “harmless”, “reduced” and “resourced”, we have developed a sand washing wastewater treatment system.

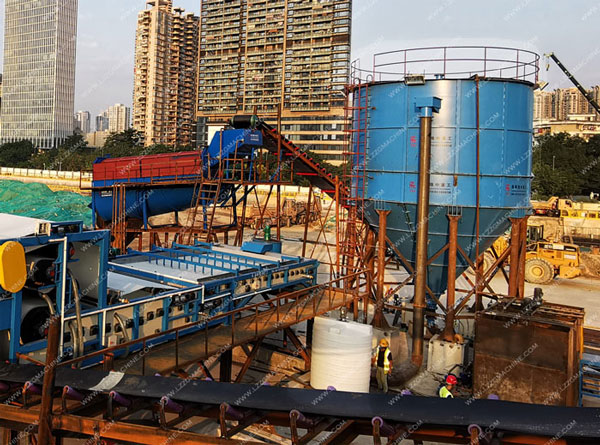

Our Shenzhen Subway Waste Slurry Low Emissions Project fully utilizes and recycles wastewater and waste residue. The sand, mud, and water of the entire production line have been recycled. The waste sludge has been discharged dry. It can recycle the water-energy after sedimentation to achieve the low-emission environmental protection requirements.

1. Fine material recovery

The overflow of the fine sand recovery machine enters the tailwater collection tank through the pipeline. The tail water is driven into the separator by the slurry pump, and the sediment is separated by the separator. After the recovery, the fine material is discharged to the dewatering screen and coarse The materials are evenly mixed and dewatered before being discharged. The outlet is connected to a belt conveyor to convey the finished material to the designated position.

2. Solid-liquid separation

At the same time, the content of suspended mud in the water after the separator is not more than 5%, and the tailwater is pumped into a high-efficiency deep cone thickener by a pump for mud-water separation. After the settled tail water is processed into clear water, it enters the clear water tank directly from the overflow port.

3. Sludge dewatering

The concentrated mud is pumped into the belt filter by the pump through the bottom of the sludge thickening tank. The filter press presses the concentrated mud into a cake, which can be used for dry stacking, landfilling or other purposes. After the filter press, the clear water enters the clear water tank to realize the recycle of clear water and zero discharge of the entire process.

River pebbles are commonly used raw materials for sand making. With the gradual prosperity of the sand and gravel industry in recent years, the performance advantages of sand making equipment…

At present, the domestic sludge dewatering and drying device mainly include 4 forms. Vacuum filtration The vacuum filter dehydrator can be continuously produced or automatically controlled, but there are many…

Hopper bottom type sludge sedimentation tank information Sludge sedimentation tank is high-efficiency sewage water sconcentration system. During the process of washing sand and washing coal, a large amount of sewage…

Thickening is a necessary part of mineral processing, and the thickener is core equipment for concentrated processing is widely used in the mineral processing and sludge dewatering industry. At present,…