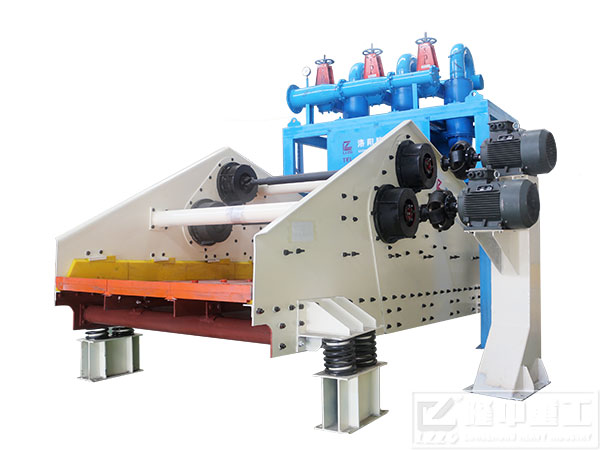

High-capacity stone powder vibrating screen

Stone powder vibrating screen is mainly used for screening stone powder after mining and crushing in quarries, and is sometimes used for ore dressing and coal dressing. Classification of materials…

published date: 08-28-2019

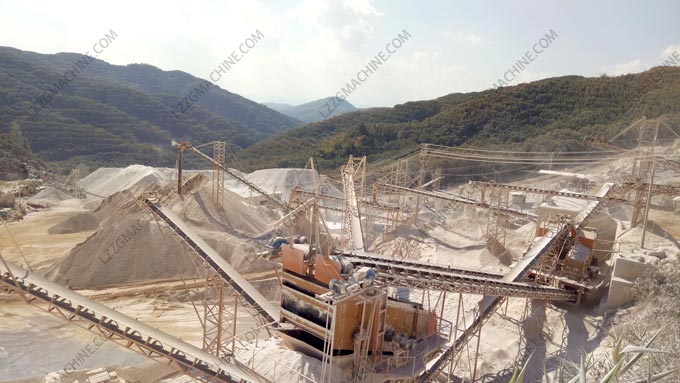

Aggregate is a granular material that acts as a skeleton and fills in concrete and mortar. The fine aggregate particles are between 0.16 and 5 mm in diameter. Natural sand, such as river sand, sea sand and valley sand, is generally used. When natural sand is lacking, artificial sand ground with a hard rock can also be used;

The coarse aggregate particles are larger than 5 mm in diameter. Crushed stone and pebbles are commonly used. Under the same conditions, the strength of gravel concrete is higher than that of pebble concrete, but the crushed stone is crushed by rock and the cost is higher than that of the pebbles. The coarse aggregates commonly used in lightweight aggregate concrete include natural porous rock such as pumice, artificial porous aggregates such as ceramsite and expanded slag.

As the main raw material in concrete, gravel and aggregate play a skeleton and support role in the building. When mixing the cement, the cement is mixed into a thin paste. If it is not added, it will not form, which will make it unusable. Therefore, aggregate is an important raw material in the building.

The fine aggregate should be hard, clean and well graded; the fineness modulus of artificial sand should be in the range of 2.4 to 2.8, and the fineness modulus of natural sand should be in the range of 2.2 to 3.0. The use of mountain sand and coarse sand should be tested and demonstrated.

The moisture content of the fine aggregate should be kept stable, and the moisture content of the artificial sand saturated surface should not exceed 6%. If necessary, accelerated dewatering measures should be taken.

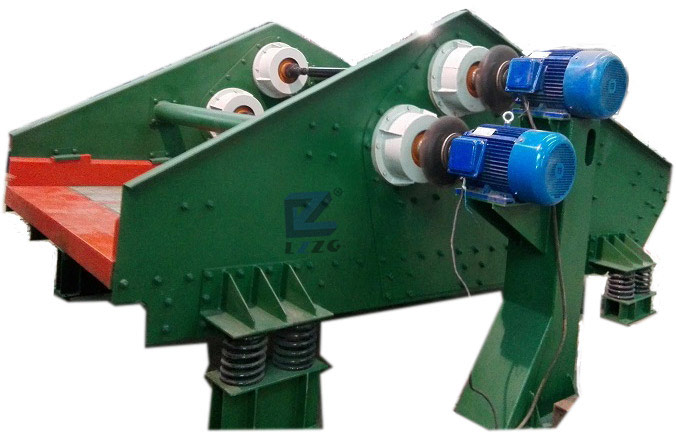

TS dewatering screen

It is important for some owner to get dry sand directly after washing process, here comes our new type vibrating dewatering machine. Also we use high quality PU screen as its sieve, one side you can get fine sand and also dry sand at the same time.

TS dewatering screen is mainly used in mining, construction for coarse or fine sand dehydrate processing.With the advantages of simple structure and easy maintenance,

Gp dewatering screen

The high waste water content of tailings is one of the main areas of concerning for the mining industry now. Mine operators are increasingly adopting all kinds of tailings disposal methods to minimise the impact of the tailings on the environment.

Sand washing and dehydrating machine

The washing plant designed to provide bigger capacity and higher cleaning level than traditional ones. It is also called “stone washing machine” as its input materials size at most can be 30mm. The whole machine has a reasonable structure and small area, which greatly reduces the investment cost for customers in the sand washing link. It integrates heavy water washing and fine sand dehydration and recycling.

Stone powder vibrating screen is mainly used for screening stone powder after mining and crushing in quarries, and is sometimes used for ore dressing and coal dressing. Classification of materials…

The excitation force, vibration frequency and screening effect of the dewatering screen are closely related. Too small excitation force will cause poor screening effect, and excessive excitation force may cause…

The circular vibrating screen for mines plays a role in sand grading in the sand making plant. It has the characteristics of low noise, high efficiency, small size, and fast…

Vibrating screen is an auxiliary equipment in the production of mines, coal mines, electric power, steel and other industries. It can also be used in chemical, food, building materials, and…