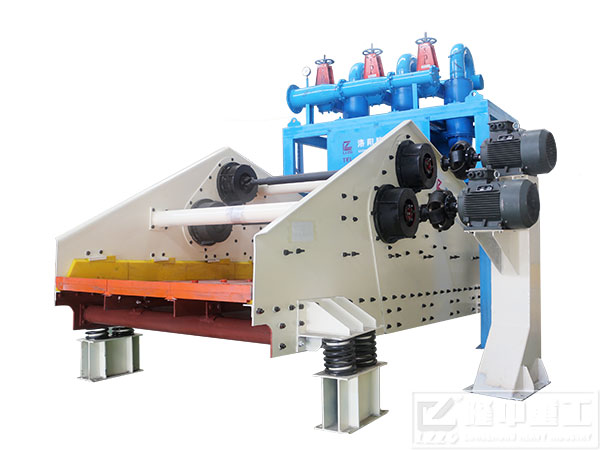

Screening equipment for calcium carbonate, kaolin , silica sand

May.18,2019

May.18,2019

Kaolin screening process

1. The material of the vibrating screen sieve is made of high molecular polyurethane, which is resistant to impact, low temperature, abrasion, chemical corrosion, self-lubricating and absorbing impact energy. The impact resistance is high in all plastics. The wear resistance is better than that of polytetrafluoroethylene, nylon, carbon steel and other materials.

2. The vibration motor of the kaolin dewatering screen is easy to replace, and the rubber spring of the base is used for shock absorption so that the amplitude is not large, the vibration is slow, and it can be cleaned off.

3, dewatering screen can be customized according to the output and water content, the side panel of the fuselage has a reinforcing plate, the bottom is equipped with support, the bottom is marked with a horizontal bar, the discharge port is supported by a triangular steel plate, and the plate is thick.

4. The vibration motor is fixed with high-strength bolts, and the bottom spring is rubber spring. The quality of the spring will affect the life of the vibration motor. The sieve plate is fixed in a high density, and the sieve plate is provided with reinforcing ribs.

5. After the welder has welded, the weld hole will not appear strictly, and the bottom is supported by channel steel.

6. In addition, the sieve hole can be adjusted according to needs, the equipment noise is small, and the dewatering effect is good.

7. Before delivery, the staff will debug it, whether the vibration motor is normal, and whether the vibration exciter is running well, to ensure the factory output is guaranteed for the customer.