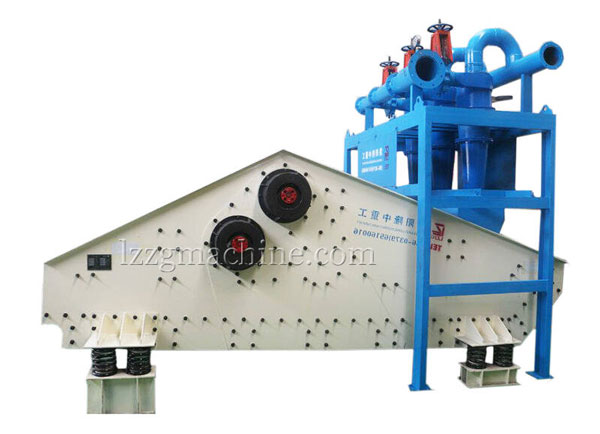

Tailings Dewatering Screen for tailing disposal

Tailing dewatering screen is high efficiency in tailing treatment

The high wastewater content of tailings is one of the main areas of concerning for the mining industry now, and mine operators are increasingly adopting all kinds of tailings disposal methods to minimize the impact of the tailings on the environment.

Tailing dewatering screen is specially designed for mineral tailing recycling, which combines the characteristics of mineral tailing with a high-frequency sieve. The dewatering unit consists of hydro-cyclones, linear motion vibrating screen, slurry pump, and attachments.

Application: It is mainly used for iron ore, copper, gold and aluminum ore tailing dehydration. It is a new type tailing recovery machine.

Working principle

GP series mine tailing screen is driven by two vibrating motors, which make the screen sieve move to-and-for on line to achieve the filtering purpose. With the vibration of the screen, the concentrated tailing materials are continuously thrown up and down on the screen, and the materials are loosened and crashed to the sieve, the small size materials are filtered away from the sieve holes. Finally, it reaches the aim of classifying, dehydrating and desliming.

Product Features

1. High efficiency, strong vibrating force and large capacity.

2. Simple structure and easy operation and maintenance.

3. 45°angle install increases the dewatering area.

4. Vibrating frequency is adjustable to meet different ores.

5. Torsional shear type high strength bolts are used between side plates and beam. No weld gap avoids side plates cracking during vibrating.

6. Polyurethane screen with better elasticity and fewer blocks. The PU side push plates protect the equipment from the rushing material and guard the long life of the whole device.

Technical parameters

| Tailings dewatering screens | Feed Size (mm) | Capacity (t/h) | Screen Panel (mm) | Hydrocyclone (mm) | Power (kw) | Weight (kg) | Overall Size (mm) |

| GP1530-65 | ≤10 | 60-100 | 1500*3000 | 300*2 | 5.5*2 | 3500 | 3250*5560*3000 |

| GP1836-75 | ≤10 | 80-120 | 1800*3600 | 350*2 | 7.5*2 | 5600 | 4000*5560*3520 |

| GP1842-100 | ≤10 | 80-120 | 1800*4200 | 250*4 | 7.5*2 | 6120 | 4600*5560*3520 |

| GP2442-100 | ≤10 | 120-180 | 2400*4200 | 250*4 | 11*2 | 7960 | 4600*6050*3600 |

| GP2448-120 | ≤10 | 120-180 | 2400*4800 | 300*4 | 11*2 | 8830 | 5220*6050*3600 |

| GP3048-140 | ≤10 | 180-240 | 3000*4800 | 350*4 | 15*2 | 9640 | 5010*7860*3720 |