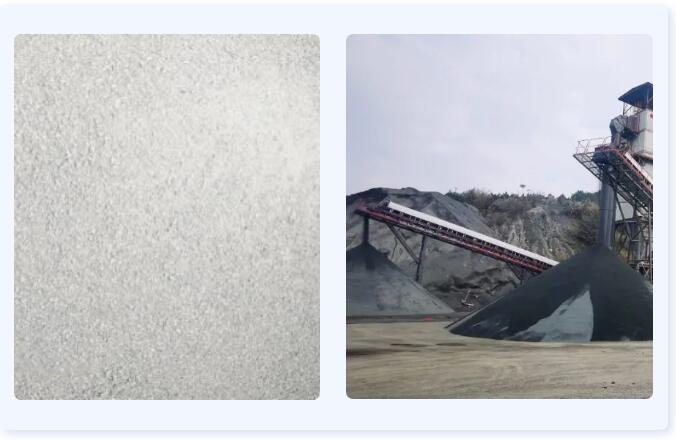

Design of 500 tons/hour river pebble sand making and sand washing production line

May.14,2019

May.14,2019

Combined with regional users

When configuring a 500-ton river pebble sand-washing production line, due to the natural environment of different areas, some areas are more rugged, and some areas are flat. Therefore, it is necessary to combine different regional environments in order to make this sand-making. The production line can meet the production needs of the company.

According to the user’s production needs

Every user has different requirements for sand and gravel materials. Therefore, in the sand production line, the finished product of the river pebble material must meet the requirements of the enterprise to meet the needs of the enterprise construction. Therefore, the user is combined with the user to configure the 500-ton river pebble sand making and sand washing production line. The production needs can make the company create higher profits.

500-ton river pebble sand making and sand washing production line configuration process

Due to the characteristics of the river pebble material, the process of configuring the sand washing plant mainly includes the process of crushing, sand making and decontaminating. The process is mainly for:

Broken: Because the river pebble material has a large particle size, it cannot be directly placed in the sand making equipment for sand making in sand making, so it needs to be crushed.

Sand making: It is through the sand making a machine to process the river pebbles into mechanical sand to meet the needs of the construction industry and other departments.

To remove impurities: In order to improve the fineness of the finished products of the river pebble materials, it is necessary to go through the sand washing machine to carry out the miscellaneous operations, so as to improve the discharge of some impurities and obtain the high-quality river pebble mechanism sand finished products.

The production of 500 tons of river pebble sand making and sand washing production line requires the production line design experience of the manufacturer. LZZG has many years of manufacturing experience, aiming at the needs of users and helping users to create higher corporate value. Technical support.