Double shaft hammer crusher for sand making

October.18,2021

October.18,2021

The traditional dry sand making process uses hammer crushing machine made sand to analyze the advantages and disadvantages of the powder content, grain shape, grading effect, yield, equipment wear rate and other factors of the finished product.

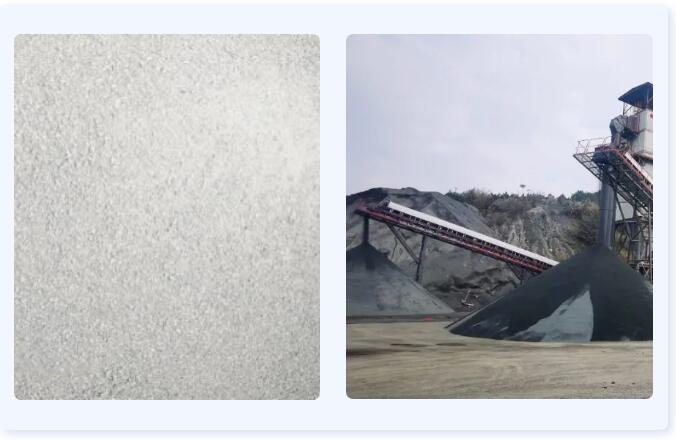

Double-shaft hammer crushing machine-made sand

The equipment is mainly composed of a machine body, a crushing plate, an upper rotor, a lower rotor, a pendulum, a rotating drive device, and a sieve plate.

During the working process of the machine, the two rotors rotate relative to each other. The material that enters the crushing chamber is first crushed by the hammer on the first rotor and hits the second rotor after gaining a certain amount of kinetic energy. The coming direction is opposite. At this time, the impact speed of the second rotor on the material is equal to the superposition of the two speeds. After so many cycles of impact, the material is broken and discharged through the gap of the grate.

Hammer crusher advantage

(1) The relative operation of the two rotors drives the materials in the crushing cavity to collide with each other. Repeated collisions of materials form the self-crushing of the stones in the crushing cavity, which greatly reduces the consumption of hammers and wear-resistant parts.

(2) The materials in the crushing cavity are thrown out by the two rotors along the tangential direction, forming repeated high-speed collisions with each other, so the crushing ratio is large, the output is high, and the yield is high.

(3) At the same time, due to the large output and simple equipment structure, its unit machine-made sand products have low power consumption and low operating costs.

Hammer crusher shortcoming

(1) Because this process only adjusts the particle size, particle gradation and fineness modulus of the product by adjusting the gap between the grate bars, the grate bars need to be replaced during adjustment, which takes a long time.

(2) The adjustment range of gradation and fineness modulus is limited by only replacing the grate bars, and the controllability of product quality is not high. Generally, only Type III sand can be produced. Therefore, there are not many manufacturers of machine-made sand using this process.