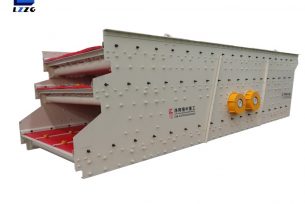

Mining vibrating screen for ore separation

Four-layer mining vibrating screen has a double-bearing screen box with two flange-mounted bearings on the shaft. It is applied in screening of quarry ore, product grading in building materials industry. The outer end of the screen box shaft is equipped with a flywheel and a counterweight and pulley. The screen box shaft is driven by three V-belts mounted by the motor mounted on the sub-frame. The sub-frame is rigidly connected to the machine chassis, and the screen box spring is used to support the screen box.

Working principle

Product Features

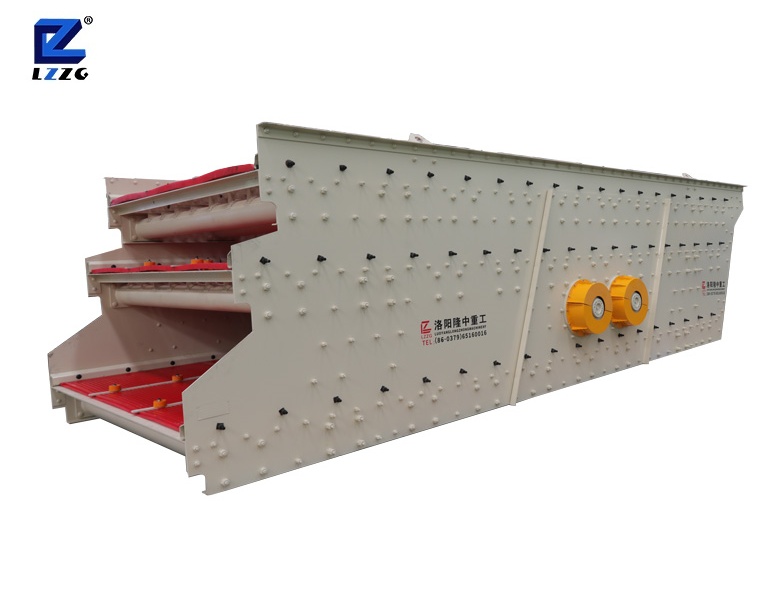

The components of mining vibrating screen:

1. Screen box: It is made of several kinds of steel plates with different thicknesses and has certain strength and rigidity. It is the main component of the screen machine.

2. The screen frame is divided into two types: one made of pine or a small amount of wood, which is mainly used to keep the screen flat and to achieve normal screening. The other is made of welded profiles, and the screen is not easy to loosen.

3. Feeding port: The feeding port is divided into two types: the conventional feeding port, and the other feeding port with the distributor can quickly distribute the material on the entire section of the screen, and the screening is more

4. Discharge port: Different discharge ports can be designed according to the different production process requirements of the manufacturer to meet the needs of customers.

5. Screen: There are screens or mesh screens made of low carbon steel and stainless steel wire.

6, vibration motor: 6, use and maintenance methods, see the vibration motor instruction manual.

Technical parameters

| Model | Feed Size (mm) | Capacity (t/h) | Screen Panel (mm) | Screen Area (m²) | Power (kw) | Weight (kg) | Overall Size (mm) |

| 2YA1230 | 0-200 | 0-80 | 1200*3000 | 3.6 | 3 | 1300 | 3200*2400*2400 |

| 3YA1230 | 0-200 | 0-80 | 1200*3000 | 3.6 | 5.5 | 1700 | 3200*2400*2700 |

| 2YA1548 | 0-200 | 0-160 | 1500*4800 | 7.2 | 11 | 3900 | 5000*2900*2900 |

| 3YA1548 | 0-200 | 0-160 | 1500*4800 | 7.2 | 15 | 4900 | 5000*2900*3400 |

| 2YA1848 | 0-200 | 0-200 | 1800*4800 | 8.64 | 11 | 4500 | 5000*3400*3000 |

| 3YA1848 | 0-300 | 0-200 | 1800*4800 | 8.64 | 15 | 5500 | 5000*3400*3500 |

| 2YA1860 | 0-200 | 0-200 | 1800*6000 | 10.8 | 15 | 5000 | 6200*3400*3500 |

| 3YA1860 | 0-300 | 0-200 | 1800*6000 | 10.8 | 22 | 6200 | 6200*3400*4100 |

| 2YA2160 | 0-200 | 0-250 | 2100*6000 | 12.6 | 22 | 6000 | 6200*3700*3500 |

| 3YA2160 | 0-300 | 0-250 | 2100*6000 | 12.6 | 22 | 7000 | 6200*3700*4100 |

| 2YA2460 | 0-200 | 0-300 | 2400*6000 | 14.4 | 22*2 | 10000 | 6200*4100*3800 |

| 3YA2460 | 0-300 | 0-300 | 2400*6000 | 14.4 | 30*2 | 12000 | 6200*4100*4400 |

| 2YA2472 | 0-200 | 0-300 | 2400*7200 | 16.8 | 22*2 | 11000 | 7400*4000*4000 |

| 3YA2472 | 0-300 | 0-300 | 2400*7200 | 16.8 | 30*2 | 13000 | 7400*4100*4600 |

| 2YA3072 | 0-200 | 0-300 | 3000*7200 | 21.6 | 30*2 | 15000 | 7400*4700*4100 |

| 3YA3072 | 0-300 | 0-300 | 3000*7200 | 21.6 | 30*2 | 18000 | 7400*4700*4700 |

| 2YA3672 | 0-200 | 0-350 | 3600*7200 | 25.92 | 30*2 | 20000 | 7400*5400*4100 |

| 3YA3672 | 0-300 | 0-350 | 3600*7200 | 25.92 | 37*2 | 23000 | 7400*5400*4700 |

| 2YA3690 | 0-200 | 0-400 | 3600*9000 | 32.4 | 37*2 | 24000 | 9200*5400*4600 |

| 3YA3690 | 0-300 | 0-400 | 3600*9000 | 32.4 | 37*2 | 26000 | 9200*5400*5200 |