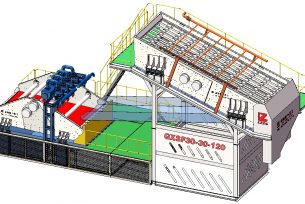

Modular Construction Waste Processing Plant

The Modular Construction Waste Processing Plant is composed of highly integrated modules, including:

Pre-screening Module

Aggregate Processing Module

Filter Press Module

Wastewater Treatment Module

Intelligent Central Control Module

Modular Construction Waste Processing Station is specially designed for construction waste recycling and resource recovery scenarios.

Core functions include sand and gravel screening and cleaning, waste separation, aggregate grading, fine sand recovery, dehydration and desludging, and concentration and grading. It can effectively remove waste impurities and produce clean, high-quality sand and gravel aggregates with extremely low moisture content.

Working principle

1. The material first enters a circular vibrating screen for preliminary screening. Materials larger than 100mm are discharged into a pile, while materials smaller than 100mm pass through an iron remover to remove metals. The material then flows via a conveyor belt to a double-screw stone washer. A spray system at the bottom of the stone washer blows lightweight debris, such as plastics and wood chips, to the upper layer, where it overflows onto a dewatering screen. After dewatering, it enters a waste bin.

2. After sand and gravel cleaning, the material enters a three-deck screen, where it is screened into three different aggregate finenesses. These aggregates are then transported to the storage yard via three separate conveyors.

3. The underflow from the three-deck screen is pumped through a slurry pump into a hydrocyclone. Centrifugal force cleans the material, controls water flow, and separates mud and sand, producing clean, fine sand. The material then enters a dewatering screen for dewatering, and then flows via a conveyor belt to the storage yard.

4. The underflow from the hydrocyclone enters the dewatering zone for dewatering. The overflow flows through a return pipe into a water tank for recirculation and cleaning, thus ensuring efficient sand washing.

5. The overflow water from the under-screen water tank enters the thickener through a water pump for preliminary flocculation and then is pumped into the filter press for filtration to achieve mud-water separation; the overflow water from the thickener and the clean water from the filter press enter the clean water tank for water circulation.

Product Features

Modular Container Design: Enhances equipment flexibility and enables rapid installation.

Global Shipping Compliance: All components strictly adhere to export container standards for worldwide tr

Convenient structural design

Comprehensive Wear Protection: All flow-path components are coated with wear-resistant materials, significantly reducing material abrasion and extending equipment lifespan.

Cyclone sand washing technology generates strong centrifugal force based on the principle of fluid dynamics, achieving high-speed and efficient separation of sand, gravel and impurities.

Convenient Maintenance Design: Pump units feature slide-out mechanism for easy servicing.

Smart Control System: PLC can automatically adjust equipment parameters according to production requirements and adaptively regulate flow