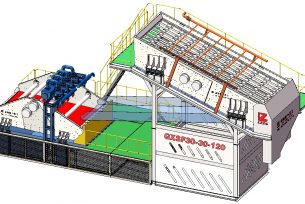

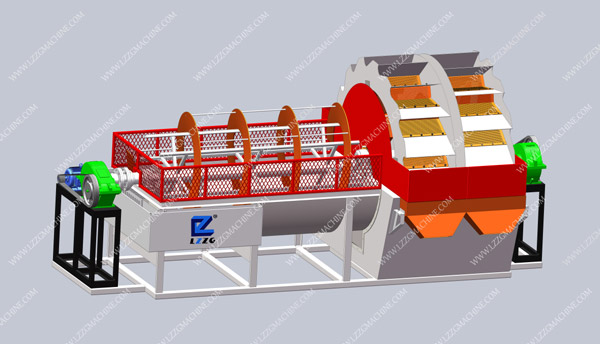

Dewatering bucket wheel for sand washing

December.26,2019

December.26,2019

Bucket Dewatering Machine Application

1. Material dewatering, Liquid-Solid Separation

2.sand and gravel washing and Classification

3.Screens or Dredging Sand Recovery

4.Waste Scavenger Recovery

Working Principle

The sand water mixture enters the wheel washing tank and is removed from the wheel bucket after washing. The tailwater (including a large amount of fine sand) after sand washing enters the spiral water tank for fine sand sedimentation, and the fine sand after sedimentation is pushed by the slowly rotating spiral blade. Into the wheel wash tank, and then with the coarse sand was taken out by the wheel bucket. By adjusting the slab at the end of the spiral water tank, the amount of fine sand loss can be controlled to achieve the desired effect of fine sand recovery; in the case of special materials and fine particles are discarded, the backwashing device is opened, and the water column is sprayed from the bottom of the spiral water tank to prevent fine sand. The sedimentation and the reverse rotation of the spiral advance the tailwater to the overflow port so that the fine sand is discharged together with the wastewater.

The speed of the spiral can be controlled to adjust the fine sand recovery effect because low speed will cause less friction and better recovery of fine materials. At low speeds, the wear of easy-to-wear parts is also very low, which makes bucket wheel dewatering machines one of the most economical sand washing solutions.