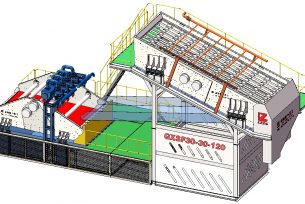

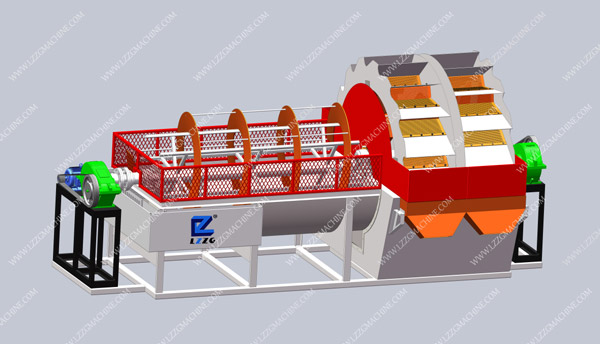

Sand washing and recovery unit with bucket classifier

November.01,2019

November.01,2019

A new type of fine sand washing recovery system

The spiral fine sand recovery system consists of a bucket classifier and a screw sand washer, which integrates sand washing and fine sand recycling. The combination of sand washing and recycling can realize the functions of sand washing, dehydration, and deliming. The structure is reasonable and the operation is simple. It is suitable for the simultaneous production of sand with different particle sizes. The better sand washing effect can meet the needs of customers. The equipment covers a small area and the fine sand recovery rate is high, which greatly reduces energy consumption, energy-saving, and environmental protection. Applicable to mining, sand and gravel plants, construction, water conservancy, and hydropower industries.

The equipment combines a spiral impeller with a bucket-type classifier. The integrated machine is mainly divided into a sand washing part and a fine sand recycling part; the sand washing part is substantially the same as a general wheel type sand washing machine, and the equipment is characterized by adding a partition at the sand washing part. The plate can simultaneously clean two kinds of particles with different particle sizes to achieve the functions of sand washing, dehydration, and deliming. The fine sand recovery part is different from the traditional cyclone recovery fine sand. The equipment uses a large-diameter, low-speed spiral impeller to slowly push the fine sand deposited in the spiral water tank into the wheel washing tank, and then the bucket belt The muddy water that has settled through the fine sand overflows from the end of the spiral. At the same time, an adjustable overflow weir is provided at the end of the spiral water tank, and the amount of fine sand recovery can be controlled by adjusting the height of the seesaw.

Working principle

The sand water mixture enters the wheel washing tank and is removed from the wheel bucket after washing. The tailwater (including a large amount of fine sand) after sand washing enters the spiral water tank for fine sand sedimentation, and the fine sand after sedimentation is pushed by the slowly rotating spiral blade. Into the wheel wash tank, and then with the coarse sand was taken out by the wheel bucket. By adjusting the slab at the end of the spiral water tank, the amount of fine sand loss can be controlled to achieve the desired effect of fine sand recovery; in the case of special materials and fine particles are discarded, the backwashing device is opened, and the water column is sprayed from the bottom of the spiral water tank to prevent fine sand. The sedimentation and the reverse rotation of the spiral advance the tailwater to the overflow port so that the fine sand is discharged together with the wastewater.

Advantages of sand washing and recovery system

1. It is improved by combining with the traditional wheel sand washing machine, so that one or two kinds of sand with different particle sizes can be produced, which can meet the requirements of more users. And the sand washing effect is better.

2, the work efficiency is relatively high, compared with the cyclone recovery fine sand can more prominently change the equipment advantages, not only can achieve a good fine sand recovery effect and can greatly reduce energy consumption, energy saving and environmental protection.

3. The high-capacity variable speed double bucket wheel provides longer drainage time for dry finished products.

4. Reasonable structure, small floor space, simple installation and convenient maintenance.

5, long service life, reduce the number of wearing parts, maintenance and operation costs to a minimum.

6, can be tailored to specific models according to customer requirements.