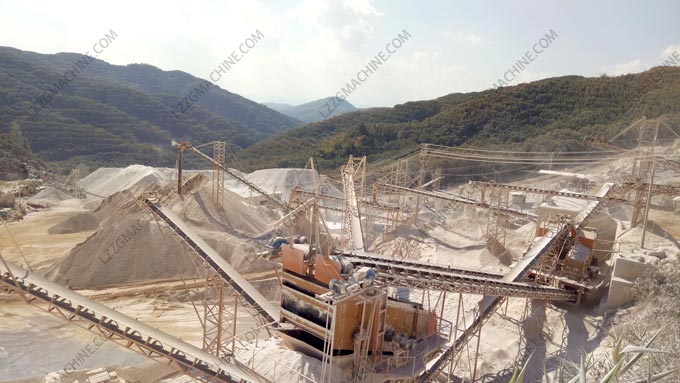

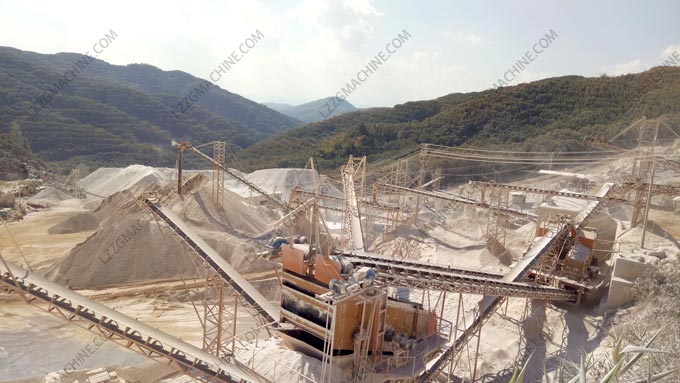

The sand washing production line can be composed of multiple sand washing equipment, feeders, vibrating screens, conveyor belts and other auxiliary equipment. The main function is to wash and screen river pebbles, bluestone, granite, basalt and other stones. Form finished aggregates with uniform grain size and reasonable gradation, which are used in highway, railway, water conservancy, construction and other basic projects.

The process design of sand washing production line

A properly matched sand washing production line can reduce energy consumption by 30% and increase output by more than 20%. The following is the process flow of 300 tons per hour sand washing production line

1. Feeding: feed the materials evenly into a section of coarse crushing equipment through the vibrating feeder;

2. Coarse crushing: the first stage of coarse crushing jaw crusher performs primary coarse crushing of the material, and after crushing, it is conveyed to the second stage of crushing through the conveyor belt;

3. Medium crushing: The second-stage impact crusher has a large feed inlet and can accept various types of coarse crushed materials. There are two options here. However, when the hardness of the sand making material is hard, you can choose a cone crusher or hydraulic crushing. Stronger strength; if it is medium and low hardness materials, you can choose the impact crusher. After one treatment, when the discharge reaches 55mm or less, it can enter the fine crushing process. A part of 5-10mm and 10-20mm finished products will be screened out. Other materials enter finely crushed sand;

4. Fine sand: When the second-stage crushed material is transferred to the fine crushing sand making machine, the sand will be produced, and the finished product between 0-5mm will be produced. If it does not meet the size, it will form a closed loop and return to the crushing again;

5. Sand washing: After being sieved out, 0-5mm materials flow directly into the sand washing machine for cleaning. The bucket wheel sand washing machine has a washing degree of up to 99%, and the steam drum and dust on the machine-made sand are washed out.

Design sand washing production line configuration plan for customers

LZZG has professional engineers “tailor-made” for you, and the online technicians of Longzhong Heavy Industry will create an exclusive configuration for you. Click the free customized configuration plan to get the answer.

1. Tailor-made: According to your needs, such as the hardness of the production material, the size of the production site, the specifications of the finished product and other information, various configuration plans will be designed;

2. Free installation and commissioning: a professional fleet for transportation, arrival at the production site within the contract date, installation and modulation by front-line personnel, and training of technical personnel for you;

3. All-round after-sales service: regular visits and original accessories for production line equipment are provided, so that you can worry-free production.