Simple fast sand screening equipment hot sale in Malaysia

May.17,2021

May.17,2021

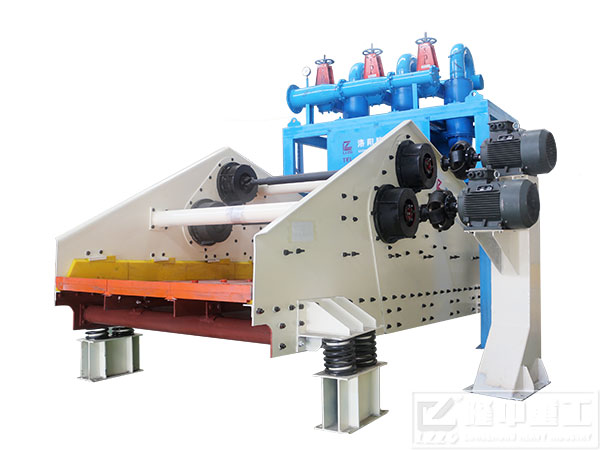

LZZG sand washing screening equipment adopts mature production technology, combined with Asian sand and gravel production experience. It has the characteristics of washing height, reasonable structure, and large output. During the sand washing process, there is little sand loss. This product has simple structure and high working efficiency. The product design is suitable for the climate, raw materials, and the environment in Southeast Asia. Features. Now exported to Malaysia, Vietnam, Cambodia, and other places of sand washing plants. It is an excellent choice for upgrading old sand washing equipment.

Processing materials: the washing of various construction sand and gravel materials such as river pebbles, stone powder, limestone, granite, river sand, machine-made sand and so on.

Scope of application: Sand screening plant can be used in construction sites, gravel yards, glass factories, power stations, concrete precast stones and electrical construction sites, etc.

Brief introduction of fast sand washing production line

Material type: machine-made sand

Processing capacity: 150t/h

Water consumption: 220-280m³/h

Powder content: ≤10%

The powder content of the finished product: <3%

Principle of equipment operation

1. The material enters the elution integrated machine through the front chute for sand washing and dehydration, and the dehydrated finished sand is transported to the finished product yard through the conveyor belt;

2. The material under the sand dewatering screen is pumped to the fine sand recovery machine for fine sand recovery through the slurry pump, and the recovered fine sand is transported to the storage yard through the conveyor belt;

3. The overflow sewage from the recovery machine enters the sewage tank, and then is transported to the thickener. The thickened mud is pumped by the special pump of the filter press and sent to the chamber filter press for pressure filtration, and the mud cake is formed and discharged;

4. The clean water overflowed from the sewage thickener and the clean water discharged from the filter press are returned to the clean water tank for recycling and reuse.