Design of Stone Silo for Limestone Sand Making Plant

December.15,2020

December.15,2020

Raw material silo design

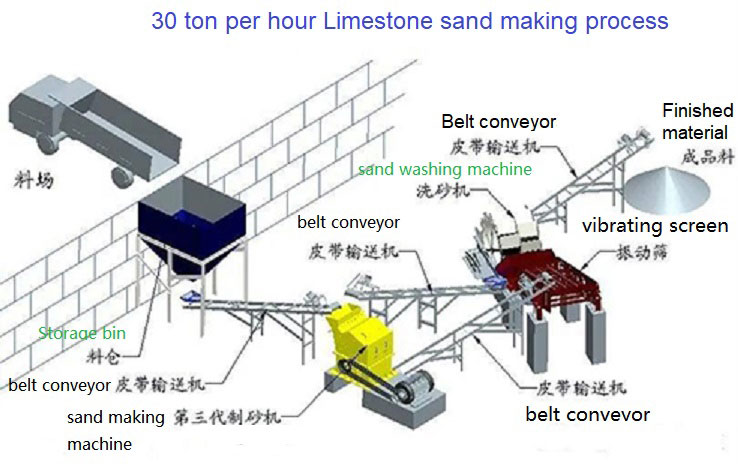

The feed module should select the feeder or the ground bin according to the site conditions and the ratio of raw materials. The material platform feed uses the height difference to provide gravitational potential energy to the raw materials, which facilitates the entry of large stones and the advance separation of natural sand. However, it is necessary to use the terrain to form a high material platform to facilitate the entry of raw materials; the silo feeds through the construction site Pit, the raw material poured into the pit is transported to the production workshop by the conveyor belt. This form has a smaller investment than the feeding platform and is convenient for construction. However, it cannot handle too large stones. If there are too large stones or too sharp stones, it may The raw material transportation belt is damaged, which affects the production schedule of the entire factory.

Adjust the silo (transfer silo) design

For production lines with large changes in the composition of raw materials such as river pebbles, it is necessary to set up a transfer silo before the medium crushing stage. The size of the silo should generally be able to stack aggregates for the crushing equipment to operate for 2 to 3 hours. Due to the large changes in the composition ratio of river pebble materials, a transfer buffer silo is set up in the process to buffer the sudden increase in load or sudden idling of the crushing equipment caused by the excessive sand or excessive pebble content of a certain batch of raw materials to ensure the smooth operation of the equipment and balance Contribute.

Product silo design

The product warehouses are mostly rectangular workshops, which are divided into different product rooms by partition walls. High concrete retaining walls are recommended for the partition walls. The products are sent to the corresponding product rooms by belt conveyors and can be stacked directly against the wall, greatly increasing the finished product warehouse. The storage capacity makes full use of the space under the condition of relatively saving investment; at the same time, the hardening space of the product warehouse for loading should be enlarged as much as possible to facilitate the loading operation, while leaving enough buffer area for the stacking area.