Particle size of limestone powder for desulfurization

February.23,2021

February.23,2021

The desulphurization limestone powder furnace burns fully and generally uses tail flue gas desulfurization directly. The particle size of limestone powder for desulfurization is 250 mesh or 325 mesh (45 μ m), and the desulfurization effect of 325 mesh limestone powder is better.

To prepare such fine limestone powder, the mill mainly adopts Raymond mill, pendulum mill, ball mill or European mill.

In the past, Raymond mills and ball mills were used more.

Limestone-gypsum flue gas desulfurization wet process (FGD) and furnace calcium injection technology are the most mature and widely used technologies to control SO2 emission in the world at present. No matter flue gas desulfurization or furnace calcium injection desulfurization, the desulfurization medium is limestone powder, so the preparation of limestone powder becomes a prerequisite for desulphurization and improvement of desulfurization efficiency in thermal power plants and steel plants.

After years of research and use, Liming heavy Industry has developed a new type of desulphurization equipment and process, which can not only meet the limestone-gypsum flue gas desulfurization wet process (FGD), of pulverized coal boiler, but also has been widely used in the field of circulating fluidized bed (CFB) desulfurization.

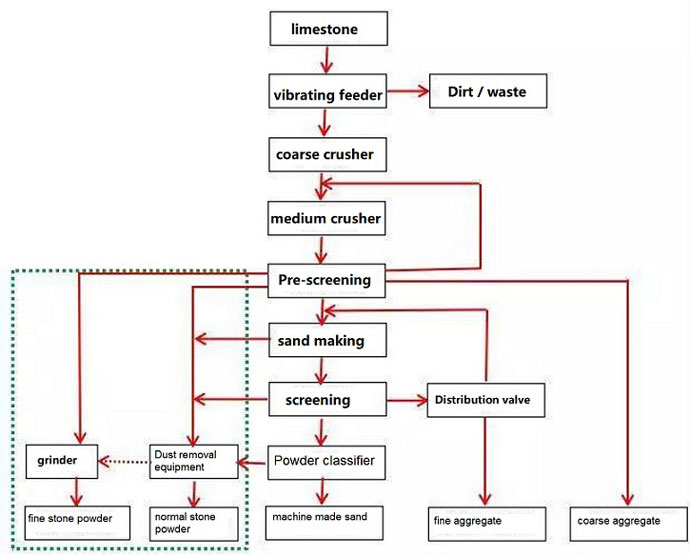

Process description

1 raw material conveying section.

After the raw material limestone is unloaded into the feed hopper through the forklift or incoming truck, the bar valve under the feed hopper is opened, and the raw material is dropped into the belt conveyor and transported to the hoist, and after lifting, it enters the limestone warehouse to achieve the purpose of uniform feeding.

2 grinding and selecting section.

The raw material falls from the silo to the metering belt machine, and after removing iron through the self-unloading type iron remover, it goes into the European mill for grinding, and the ground material is sorted through the wind force through the powder separator to select the finished powder that meets the requirements. Collect and store temporarily through the cyclone collector.

3Murray-finished product storage and transportation section.

The finished powder temporarily stored by the cyclone collector is transported to the finished product warehouse for storage by conveying equipment and hoist to meet the subsequent tanker shipment.