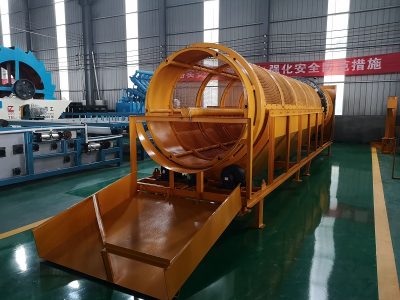

Trommel screen design, drum screen price in South Africa

May.29,2019

May.29,2019

The trommel screen is a kind of screening equipment which is classified according to the particle size of the material. It is also called the drum screen. Because of the simple process layout, it is widely used in the classification of products in mining, building materials, transportation, energy, chemical, and other industries. It is commonly used in the grading and screening of medium and fine grain materials to improve the quality of materials. Our screener machine was exported to Europe, Australia, North America, South America, Southeast Asia, the Middle East, South Africa and other countries. [Inquery the price]

Product features

The drum screen is suitable for screening materials of various properties, as well as moist and easy-clogging materials such as coal, coal gangue, coke raw lime, etc. The maximum product under the sieve is 100mm, the middle is 10-50mm, and the finest is up to 3mm. The product is well received by users. Agree.

The drum sander mainly consists of a motor, a reducer, a roller device, a frame, a sealing cover, and an inlet and outlet. The main structure of the rotary screen is a screening cylinder, which is composed of a plurality of circular screens, which are inclined with the ground plane as a whole, and the outside is sealed by a sealing spacer to prevent environmental pollution.

The trommel screening machine has low power, low energy consumption, self-cleaning device in the cylinder, and the screen hole is not easy to be blocked; the occupied space is small, the investment cost is reduced, the operation is stable and reliable, the screening efficiency is high, the output is large; the process layout is simple, installation, Easy to maintain, easy to operate and so on.

The trommel screener has strong adaptability to materials and can be mass-produced. The center screen adopts annular flat steel ring design, good wear resistance, long service life, simple structure and convenient maintenance.

The material is turned and rolled in the drum, so that the material stuck in the sieve hole can be ejected to prevent the sieve hole from being clogged. In this case, the sieve hole is not easy to be blocked, the machine itself runs smoothly, the noise is low, the structure is simple, and the maintenance is convenient. The reliability of the whole machine is high, which can reduce the investment of users.

Trommel screen installation angle and speed problem

Trommel screen maintenance manual

The installation angle of the screener is designed to prevent the large waste from occupying too much time in the trommel screen to facilitate the accurate screening of the fine sand. The size of the mesh is designed according to the requirements of many different thicknesses of the construction industry. The speed is very slow and very uniform. The drum screen itself is designed reasonably, the screen model is compact, and the movement and maintenance are convenient. It takes only 10 minutes to replace the screen bottom. The loader is loaded at one time and does not need to be transported for direct screening. The screening rate is high, the rotary screen, the screen leakage does not touch the sand, saving resources. Wet sand can be screened normally and is not affected by the weather. High work efficiency, more than 10 times the efficiency of artificial screening.