High efficiency silica sand classification spiral concentrators

December.13,2023

December.13,2023

The spiral concentrators is a commonly used gravity mineral separation equipment, suitable for sorting iron ore, ilmenite, chromite, pyrite, tungsten ore, silica sand, quartz sand and tin with a particle size of 0.6-0.05mm (can sort <2mm under special circumstances). ore, tantalum-niobium ore, placer gold ore, zircon, rutile, monazite, phosphorite and other non-ferrous metals, rare metals and non-metallic minerals with different specific gravity.

working principle

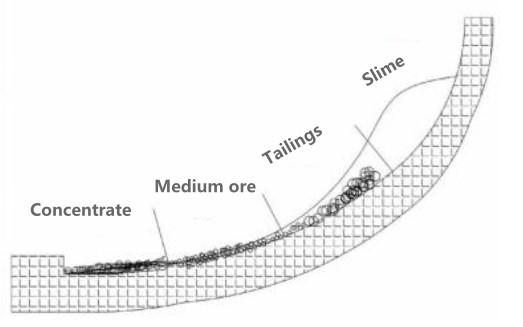

The slurry is fed into the spiral groove and flows downward along the groove surface under the action of gravity component. Since the spiral groove is spiral linear, the slurry also undergoes centrifugal rotation while flowing downward. The slurry moves downward under the action of centrifugal inertia. The outer edge of the spiral groove expands, thus forming flow characteristics with a thin flow layer and low flow velocity at the inner edge and a thick flow layer and high flow velocity at the outer edge.

The work principle of spiral concentrators classification

The solid particles located in the slurry are not only dominated by the fluid motion characteristics, but also affected by their own gravity, inertial centrifugal force and tank bottom friction. After the slurry is fed to the spiral groove, it is loosened under the action of weak turbulence, and then stratified according to the flow film separation principle. Under the action of external force, the mineral particles perform centrifugal rotation along the groove surface, generating inertial centrifugal force. Due to the high settling speed, heavy minerals with high density enter the bottom layer of the flow film. Affected by the friction force at the bottom of the groove, the movement speed is low and the inertial centrifugal force is small. Under the action of the gravity component, it moves toward the inner edge of the groove along the maximum inclination direction of the groove surface; the light mineral particles with small density in the upper layer move together with the slurry, with high speed and high inertial centrifugal force, and are thrown toward the outer edge of the groove. Due to the different directions of movement, zones are developed on the groove surface. Heavy minerals are close to the inner ring, light minerals move to the outer ring, and fine particles of slime are suspended in the slurry in the outermost ring.

Advantages of using spiral concentrators

1. The equipment is simple, no noise, no power required, etc.

2. The sorting particle size range is wide, suitable for 0.05-0.6mm (<2mm can be sorted under special circumstances).

3. Stable mineral processing, large processing capacity, high efficiency and small footprint.