NJ-80 efficient wear-resistant vacuum mud pump manufacturer

September.17,2019

September.17,2019

Industrial vacuum mud pumps are widely used in electric power, mining, drilling, metallurgy and other industries. In the power industry, mainly used in thermal power plants. In the coal washing industry, it is used to transport coal and coal gangue. About 80% of the application of slurry pump in the concentrator is used in the mining industry.

Learn how the industrial slurry pump works:

Under the action of centrifugal force, the liquid is thrown from the center of the impeller to the outer edge and obtains energy, leaving the outer edge of the impeller at high speed into the volute casing. In the volute pump casing, the liquid is decelerated due to the gradual expansion of the flow passage, and part of the kinetic energy is converted into static pressure energy, and finally flows into the discharge pipe at a relatively high pressure and is sent to a required place. When the liquid flows from the center of the impeller to the outer edge, a certain vacuum is formed at the center of the impeller. Since the pressure above the liquid level of the tank is greater than the pressure at the inlet of the pump, the liquid is continuously pressed into the impeller.

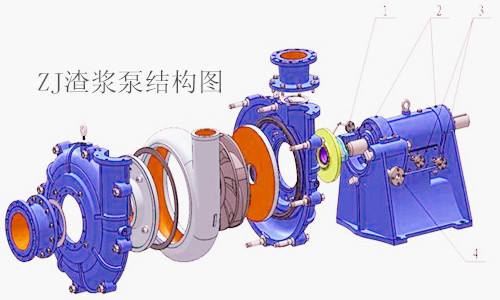

Mud pump structure

1. Power end: base, frame, pinion shaft assembly, large gear shaft assembly, crankshaft assembly, crosshead assembly, DC motor;

2, hydraulic end: liquid cylinder, suction valve, discharge valve, cylinder liner, piston, piston rod (plunger, packing and cylinder liner), suction pipe, suction air bag (to reduce water hammer phenomenon), discharge pipe, discharge Filter assembly, exhaust air package l safety valve, cylinder head, valve cover, spray pump assembly;

3. Accessories:

(1) Lubrication mechanism: lubrication of chain, lubrication of gears and bearings, cooling and lubrication of cylinder liners;

(2) Nitrogen pack: can effectively reduce the pressure fluctuation of the discharge system, thereby obtaining a more uniform liquid flow;

(3) Safety valve: When the mud pressure exceeds the set pressure of the pump, the safety pin can be quickly cut, the bypass line is opened, and the mud pump is vented, thereby protecting the pump body.

NJ-80 vacuum mud pump

LZZG mud pump performance characteristics:

The slurry pump has high operating efficiency and low loss.

The overcurrent components of the pump have a relatively long service life, saving production costs.

The entire industrial and mining system operates stably, and will not affect the work of the entire industrial and mining system due to the operation of the pump.

Technical parameter

| Pump (inlet/outlet) |

Flow (m3/h) |

Head (m) |

Power (kw) |

Rotation (r/min) |

Net positive suction head (m) |

| 4/3 | 80 | 20 | 15 | 1470 | 4 |

| 4/3 | 100 | 20 | 18.5 | 1470 | 4.5 |

| 6/4 | 120 | 20 | 22 | 970 | 3.5 |

| 6/4 | 200 | 25 | 30 | 1470 | 4.8 |

| 6/4 | 240 | 28 | 37 | 1480 | 4.8 |