JY series automatic flocculant addition system

January.28,2018

January.28,2018

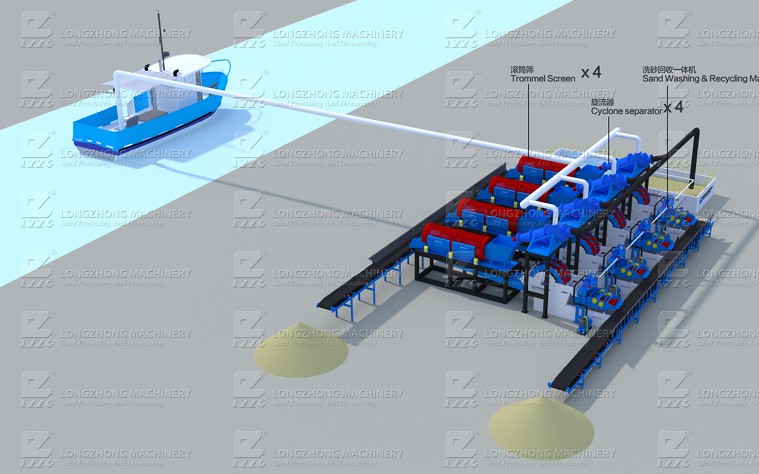

At the back end of processing operations such as mining, aggregate processing, ceramic raw material processing, silica sand production processing, and various metal ore tailings, sewage treatment processes are often equipped. It is often necessary to add a certain proportion of catalytic agents. Because the entire production process is a continuous operation, it is required that the added pharmaceuticals should also be continuous and added regularly and quantitatively. Our company’s LZ automatic dosing system achieves the above functions.

The automatic dosing system is widely used in power plants, chemical plants, water plants, and mine aggregate processing tailwater. Water treatment systems that require the addition of purifiers and flocculants can provide continuous and stable required chemicals for water treatment.

Chemical agent types for automatic flocculant addition system

1. Add flocculant, disinfectant, acid, and alkali solution in water treatment

2. Add scale inhibitor, water quality stabilizer, etc. in cooling water and circulating water

3. Add acid and lye to other solutions in the chemical industry and printing and dyeing industry.

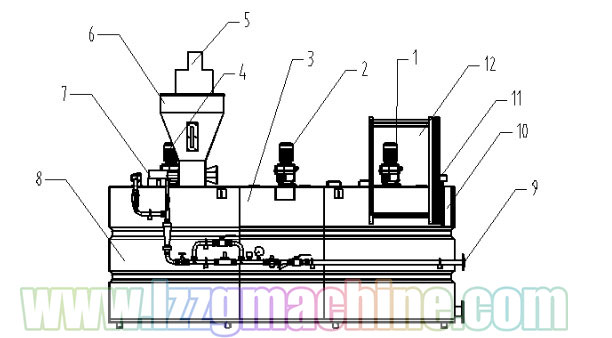

1. Storage tank agitator 2. Mature tank agitator 3. Mature tank 4. Mixing tank agitator 5. Automatic suction machine 6. Silo 7. Feeding device 8. Mixing tank 9. Water inlet system 10. Storage tank 11 . Level switch 12. Electric control box

product structure

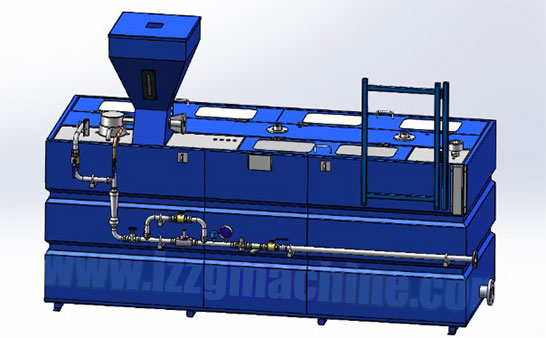

1. Dosing device mainly consists of solution tank, agitator (optional), metering pump, control cabinet, pipeline, buffer, pressure gauge, Y-type filter, liquid level gauge, liquid level sensor (optional), Conductivity (optional), pH meter (optional), corrosion online monitor (optional) bracket and other components.

2. All parts of the dosing device are centrally installed on a rack. Compact and reasonable combination into independent dosing units greatly reduces the workload of chemical design and field installation and reduces the area.

3. The solution tank is equipped with a plate level gauge, which can realize local display and has the protection function of stopping the pump when the liquid level is low.

4. Manual adjustment and automatic dosing can be realized on the spot. All electrical appliances and meters are assembled in the electrical cabinet. The structure is compact, the commissioning and operation are safe and convenient.