Vibrating screen for lignite hot press forming

July.08,2019

July.08,2019

Although lignite is low in mining cost, it is usually only used on site because of its high water content and low energy density, which is not suitable for transportation or trade. In addition, with the slowdown in China’s consumption growth, coupled with the vigorous development of US shale oil, the international coal market price is lower, which also makes the situation of relatively high-cost hard coal power plants relatively prosperous.

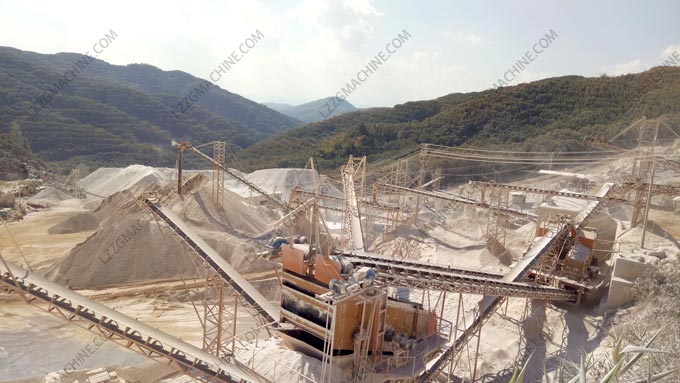

Vibrating screen can be used in Lignite quality improvement

lignite coal vibrating screen

c has high moisture and ash content, low calorific value, easy weathering in the air, and is not conducive to long-distance transportation. When used directly as a fuel, the combustion efficiency is low, and the greenhouse gas emissions are high and the pollution is serious, which has been greatly limited for a long time.

The upgrading of lignite refers to the reduction of moisture in lignite by thermophysical or thermochemical methods, and the increase of the calorific value of the product, which is convenient for transportation, high heat utilization efficiency and low pollution.

In Germany, coal-fired power generation has not only been squeezed out of the market by clean fuels, but has always been stable. Anthracite and lignite power generation accounts for more than 40% of Germany’s total electricity production. Among them, the proportion of lignite has been stable at around 25%. At present, lignite accounts for 12% of the primary energy consumption structure in Germany.