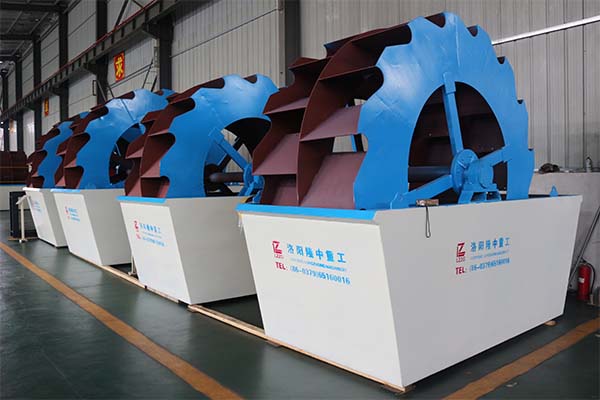

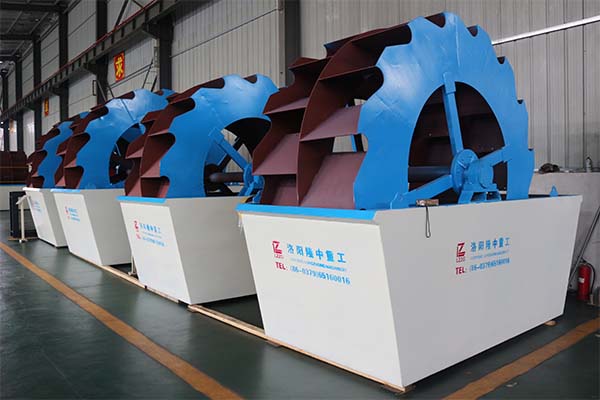

Wheel sand washing machine is a device for cleaning sand that with simple structure, but there are some items are need to pay attention to from the select model, purchase, installation and operation, especially for some customers that not very clear about sand washing machines. Some characteristics and installation precautions for you as follow.

Characteristics

1.The impeller driving device of sand washing machine is isolated from water and water-receiving material, which greatly avoids the damage of bearing due to water immersion, sand and pollutants.

2. Reasonable structure, convenient maintenance, large processing volume, small power consumption, high washing degree. The novel sealing structure, fully sealed oil bath transmission and adjustable overflow slab ensure the high efficiency, durability, good cleaning and dewatering effect, and the fine-grained products remain uncluttered of sand washing machine.

3.Used for washing, grading and dewatering of smaller granules in construction sites, sand and gravel plants, glass plants, hydropower stations, etc.

Points to be aware of when installing and operating sand washing equipment

1.Should be installed on a horizontal concrete foundation and fixed with anchor bolts.

2. Keep the main body horizontally and vertically when installing the sand washing machine,

3.After installation, check whether the bolts in all parts of sand washing machine are loose. If any, tight them.

4.Check the configuration power cord and control switch of sand washing device.

5.Before starting the machine, it is necessary to check the lubrication points. If there is enough grease, the connecting bolts must be tightened and the spiral blades must be tightened.

6.After the inspection is completed, sand washing equipment is subjected to an empty load test, and the test can be carried out normally.

7.After starting the motor, you must wait for the normal operation before you start feeding gradually.

8.The feed must be stopped before stopping the operation, and the motor can be stopped after all the materials in the tank have been drained.

9.Frequently check the wear and tear of sand washing equipment impellers in time to avoid unnecessary loss due to damage.