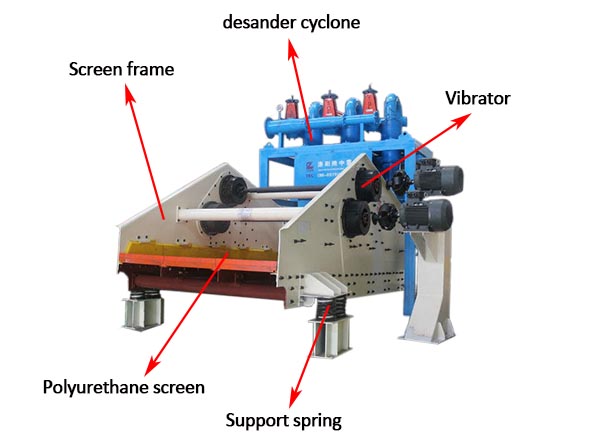

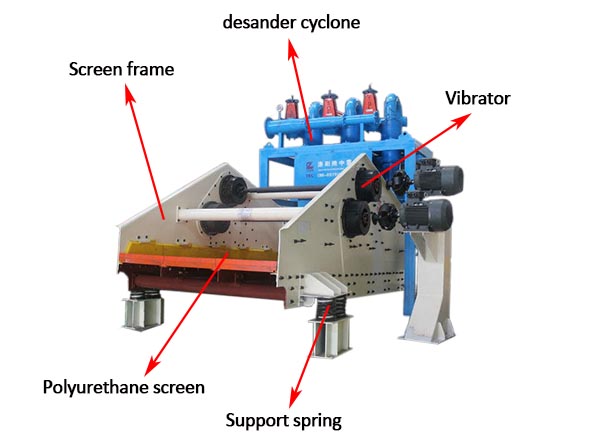

LZZG has been committed to the research and development of mine tailings treatment system for many years. LZ series tailings dewatering screen a tailings disposal methods specially developed on the basis of high frequency dewatering screen and combining the features of metal tailings. It is mainly used for iron ore, copper ore, gold ore and aluminum, demineralization of mine tailings. Mining waste disposal methods are a great leap forward for LZZG in tailings dry diaposal technology, which has injected new vitality into the development of LZZG in mine tailings treatment.

Working principle of mine tailings treatment machine

Tailings are evenly fed into the feed inlet by feeding box. About 1/3 of water is removed firstly at the level of 45 degrees, then move forward and accumulate at the joint of the flat sieve plate and inclined sieve plate. The water and fines settled by gravity, and began to form a thinner filter layer, which in turn prevented the remaining particles from passing through sieve mesh, so that the filter layer gradually thickened. The water that fails to pass through screen forms a pool in the upper part of filter layer, then gradually removes under strong motion because of the thinner filter layer here. Then due to the high-frequency low-amplitude vibration state, tailings is more and more dense, and forms filter cake to be discharged at discharge opening. The residual water in tailings will not overflow from discharge opening, and will flow to the joint pool duce to the negative inclination of screen panels.

Technical characteristics of mine tailings treatment equipment

1. High working frequency, high vibration intensity, low final water content, high processing capacity, and high solid recovery when used for tailings recycling.

2. Adopting self-synchronization technology, motor drives the vibrator through tire coupling, which has simple structure and low working noise.

3. Install at a negative inclination angle, to make the sieve surface of dewatering section at a level of 45 degrees to increase the dewatering area and promote the dehydration of material as soon as possible to form a filter layer.

4. In order to adapt to the difference in the properties of different tailings, the amplitude of sieve can be adjusted. The method is to adjust the angle between main and auxiliary eccentric blocks to meet the dewatering effect of tailings with different properties, and strive to achieve excellent process results.

5. The side plate and the beam are connected by torsion-shear type high-strength bolts, and there is no weld seam, which avoids the problem of side plate cracking caused by welding stress.

6. Adopts special bearing for vibration equipment to avoid premature damage of bearing heat. The main welded structural parts are surface treated and have a beautiful appearance.

7. Adopts polyurethane elastic screen surface, high opening ratio and elasticity, which is beneficial to dehydration. The screen surface is installed by rail seat, which can conveniently maintain and replace. The side plate of screen is also made of polyurethane material, which can be effectively protected from material flushing.

8. The surface of underbeam is coated with an anti-wear coating to prevent beam from breaking prematurely.

9. The finite element structure analysis software is adopted to ensure the strength, rigidity and force of screen frame are reasonable, and the weight is light, and the energy consumption is small.

10. The user can be equipped with a structure with a bottom frame and a feeding box as needed to facilitate installation and debugging.