Fine sand coarse sand vibration screening machine

YK series circular vibrating screen can screen out various specifications of sand. The rocks suitable for sand making, such as river pebbles, limestone and granite, go through the crusher and…

published date: 11-12-2019

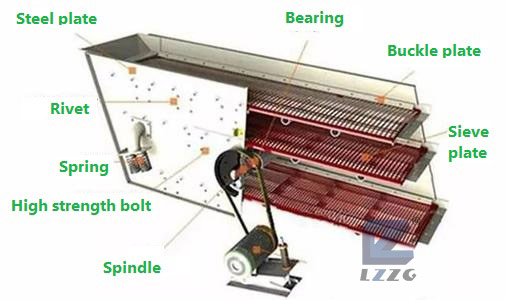

The circular vibrating sieve refers to the vibrating body of the screen machine, that is, the screen box has an inertial vibrating screen with a circular motion locus, and the vibrating screen is also called a single-axis vibrating screen. The circular vibrating screen usually has a multi-layer structure and is widely used for dry and wet classification of various granular and small bulk solid materials in coal, mining, electric power, building materials, light industry, and chemical industries.

1. Vibrating screen YA is of double decks to four decks whose moving track is round.

2. The moving track of material is very long; the size of the material can be separated into several specifications.

3. It adopts a cylinder style inspiring vibrator device and eccentric shaft to adjust. It has the features of reliable structure, strong vibrating generation, high screening efficiency, low noise, easy maintenance, safe performance, etc.

4. It is widely used in separating gravel and is also suitable for mining, construction material, transportation, energy, chemical industry and so on.

YK series circular vibrating screen can screen out various specifications of sand. The rocks suitable for sand making, such as river pebbles, limestone and granite, go through the crusher and…

Comparison of efficiency between banana sieve and circular vibrating screen The existing circular vibrating screen in the concentrator has been used for 10 years. Compared with the new screening equipment,…

Circular vibrating screen installation (1) Install supporting or hanging devices. When installing the circular vibrating screen, the ground should be shoveled and sturdy to prevent problems caused by uneven ground…

What factors should be considered when buying a circular vibrating screen is a common question. Circular vibrating screens are widely used in mining, sand and gravel, transportation, building materials, energy…