The dewatering equipment commonly used in sewage treatment equipment includes a horizontal screw centrifuge and a belt filter press, both of which have advantages.

According to the actual project, the characteristics of the horizontal screw centrifuge and the belt filter press are comprehensively compared, so that the engineering designer can better select the sludge treatment equipment.

In the past, the sludge (concentrated) of urban sewage treatment plants was dehydrated. Most of them used filter press (hereinafter referred to as belt filter presses) and decanter centrifuge because of their high noise, high energy consumption and low processing capacity. Rarely used, however, in recent years, the application of horizontal screw centrifuges (hereinafter referred to as centrifuges) has exceeded the potential of belt filter presses. There is no need to wash the water, and the strength of the belt filter press is to save power and noise. Therefore, the dewatering of sludge (concentrated) is carried out by using a centrifuge or a belt filter press. It must be detailed, detailed analysis of the detailed topics, and must not blindly follow the trend.

The centrifuge can automatically adjust the slip and torque according to the change of feed concentration. The belt filter press should be adjusted manually, in fact due to the feed concentration! The change has a greater impact on the centrifuge and less on the belt filter press.

Calculation of operating cost When the centrifuge manufacturer calculates the centrifugal dewatering and the belt filter press dewatering operation cost comparison, there are many problems in the calculation method. The operating costs mainly include: pharmacy, electricity and water. Because the nature of the sludge varies from plant to plant, it is difficult to say that the belt filter press has a higher drug consumption than the centrifuge. Taking a sewage treatment plant (8x104t/d) as an example, the actual operating cost of sludge treatment was calculated. The results are as follows: Dry sludge volume: 10t/d, solid content: 0.8% (unconcentrated sludge) The problem of power consumption, the difference in power consumption is not what the centrifuge manufacturers claim. In fact, the centrifugal electromechanical consumption is far greater than the belt filter press.

Theoretical comparison between belt filter press and centrifuge Because the belt filter press is the mainstream of sludge dewatering in sewage treatment plants, the strength of the centrifuge is mainly based on the comparison with the belt filter press. The centrifuge manufacturer believes that the centrifuge has the following advantages for the belt filter press.

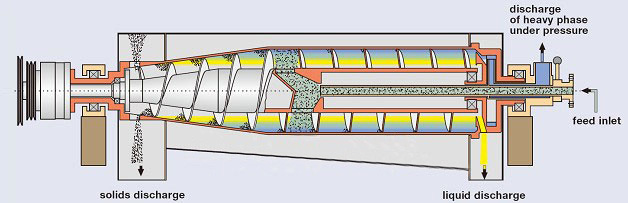

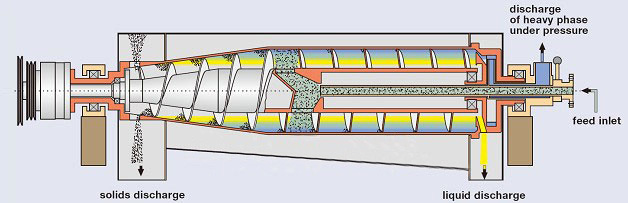

The 0 horizontal screw centrifuge uses the principle of centrifugal sedimentation to separate the solid and liquid. Because there is a filter screen, which will not cause blockage, and the belt filter press utilizes the filter. The belt is used to separate the solid and liquid. In order to prevent the filter belt from clogging, high-pressure water is required to be continuously washed. The centrifuge combines various types of sludge for concentration and dewatering. The belt filter press also uses various types of sludge, but the remaining activated sludge Need to apply a large amount of drug and dehydration problems:

When the concentration of the feed in the centrifuge is changed during the dehydration process, the difference between the drum and the spiral and the twist will be automatically tracked and adjusted, so there is no special person to operate, and the filter is changed during the dehydration process. At the time, the belt speed, belt tension, dosing amount, and flushing water pressure need to be adjusted and manipulated!