Low-cost sludge thickening equipment

April.30,2020

April.30,2020

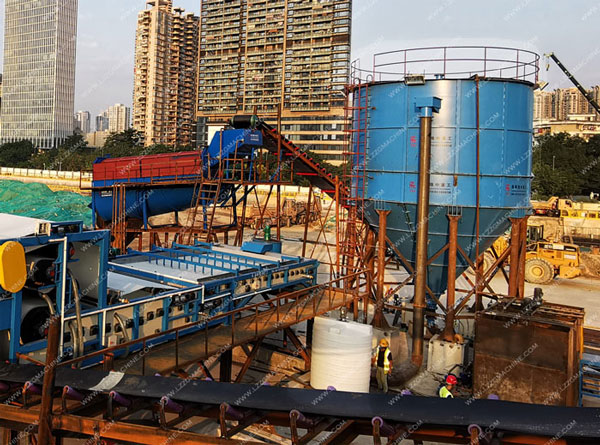

Low-cost sand washing wastewater and sludge thickening project

The sand washing wastewater is 300m3 / d and the sludge is 30m3 / d. The main production of construction water washing sand primary products. A water-washing sand production line with a daily production capacity of 150 tons will crush, screen, and wash nearby sandstone, silica, etc. to produce construction water-washing sand products.

The main environmental pollution problem in the production process of the project is the sludge wastewater and domestic sewage generated by washing sandstone and silica rock. According to the requirements of relevant laws and regulations, sand and stone washing wastewater and domestic sewage must be discharged or recycled after treatment, and the washing sludge should be properly disposed of. The tailings can be exported as good paving gravel.

Total wastewater

About 300 m3 / d of washing production wastewater. The main pollutants are characterized by a large amount of soil and silt in sandstone and silica. After crushing and washing with water, soil and fine sand are contained in the water. The content of suspended matter and colloid is high, and the color is high. The surrounding environment causes pollution. The washing wastewater undergoes the initial sedimentation, coagulation sedimentation, and then is used as sand field washing water for recycling or discharged up to standard. The sedimented sludge is pressed and dewatered by a filter press and then landfilled. The wastewater is recycled after sedimentation treatment. The recycling rate is designed according to 90%, and the evaporation and water loss are supplemented according to 10%. The domestic sewage is treated by septic tanks and used as water for plant greening and nearby agricultural land.

Comparison between decanter centrifuge and filter press

Sludge thickening is an important process for the treatment of solid waste. It minimizes the waste of water and the pollution to the environment. The sludge dewatering equipment commonly used in sewage treatment plants includes decanter centrifuges and belt filter presses, each of which has its own advantages.

Although the operating cost of the centrifuge is lower and the water content of the filter cake is lower, the filter press can be started and shut down more quickly and the operation is quieter. They are also reliable and easier to maintain than centrifuges because they require less professional care. The filter press has better applicability.

The centrifuge is not suitable for sludge with many inorganic components such as fly ash. The advantage of the centrifuge is that the sludge is dry and fully enclosed The operating environment is good. No flushing water is needed. The advantages of bringing the machine are energy-saving and low noise. Therefore, whether to use a centrifuge or belt machine for sludge (concentration) dewatering depends on the site and the nature of the sludge.