What sand washer is used for a 30 TPH capacity sand washing plant?

December.29,2025

December.29,2025

How to choose the most economical sand washing equipment for a small sand washing plant? The choice should be based on factors such as hourly processing capacity, site area, and the mud content of the raw materials.

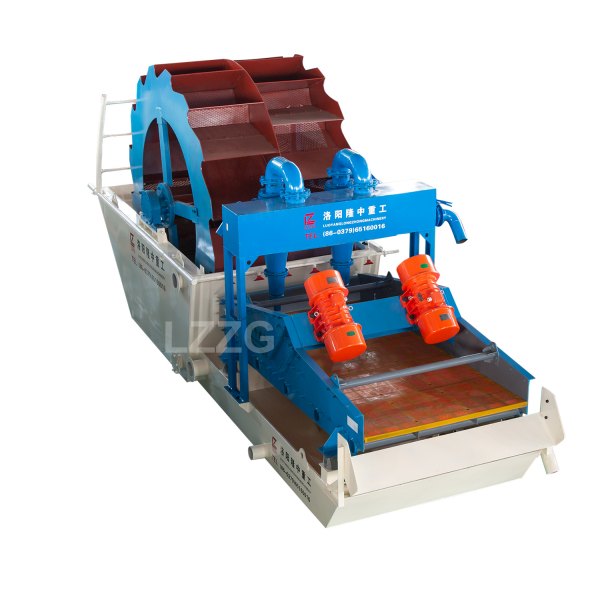

Advantages of Wheel Sand Washing Machines:

High efficiency and water saving: Closed-loop water circulation system saves 30% of water, suitable for water-scarce areas.

Low energy consumption: 20% improvement in washing cleanliness, 15% reduction in energy consumption, processing capacity 50-200 tons/hour.

Easy maintenance: High wear-resistant rubber impeller, service life over 8000 hours, few vulnerable parts.

Advantages of Spiral Sand Washing Machines:

Stable and reliable: Planetary gear reducer, failure rate <0.5%, trouble-free operation over 10000 hours.

Strong adaptability: Processes 5-100mm materials, suitable for weathered sand, river sand, manufactured sand, and tailings cleaning.

Environmentally friendly: Equipped with sedimentation tank and filter press interface, achieving zero wastewater discharge.

Sand Washing Machine Selection Guide: Capacity Matching **Output per Hour < 50 tons:** Bucket wheel sand washer (25% cost reduction)

**Output per Hour 50-300 tons:** Spiral sand washer (better stability for continuous operation)

Material Characteristics

Mud content < 10%: Bucket wheel sand washer is more efficient.

Mud content ≥ 10% or sticky materials: Spiral sand washer cleans more thoroughly.

Site Conditions

Limited space: Bucket wheel sand washer (30% space saving).

Elevation differences: Spiral sand washer allows gravity feeding (reduced conveying costs).