What equipment is needed for grinding hard coal?

November.17,2025

November.17,2025

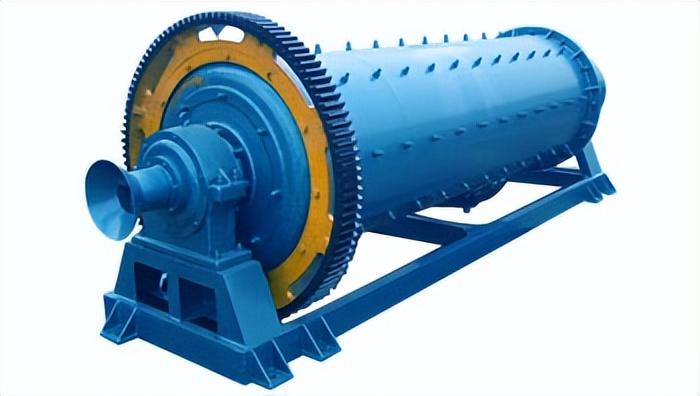

Low-speed grinding mills are mainly rotary ball mills, commonly referred to as ball mills or simply ball mills. It is a rotating cylindrical or conical drum filled with steel balls. The drum rotates at 15-25 rpm. During operation, the steel balls inside the drum continuously impact and compress the coal, grinding it into coal powder. Hot air is then introduced into the drum to dry the coal and send the coal powder out. After separation by a separator, coal powder of a certain particle size is sent to a coal powder silo or directly to a coal powder burner. Ball mills are bulky, consume a lot of electricity, and are noisy; however, they are adaptable to a wide range of coal types, operate reliably, and are particularly suitable for grinding hard anthracite.

High-speed grinding mills are not suitable for grinding hard coal. They rotate at 500-1500 rpm and mainly consist of a high-speed rotor and a mill shell. Common types include fan mills and hammer mills. In a fan mill, coal lumps are ground by the high-speed impact of the high-speed rotor, the collision with the mill casing, and the mutual impact between the coal lumps. This type of coal mill, combined with the coal powder separator, forms a simple, compact structure with low initial investment. It is particularly suitable for grinding high-moisture lignite and high-volatile, easily ground bituminous coal. However, due to high wear, the continuous operating time of the fan mill is shorter than that of other coal mills, making it unsuitable for grinding hard coal types.