The 10 most common fault troubleshooting for sand washer

July.01,2020

July.01,2020

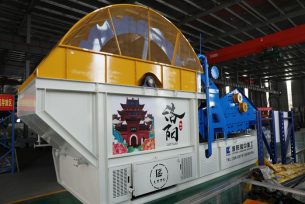

The sand washing machine is used to clean the dirt, stones and other impurities contained in river sand, rock sand, weathered sand, etc. The washed sand is commonly called “water washing sand”. Widely used in sand yards, mixing plants and various infrastructure projects.

Since the sand washing machine usually runs for a long time, it will inevitably encounter various problems, and quickly solving general failures can save a lot of time and cost.

In production, the sand washer inevitably encounters various problems.

10 troubleshooting tips for sand washer common faults

1. The machine does not start

cause of issue:

1. Insufficient voltage 2. The belt slips; 3. The reducer malfunctions; 4. The motor is damaged.

solution:

Replace the power supply, tighten the belt; repair the reducer. Replace the motor to run.

2. The machine is noisy

cause of issue:

1. The bearing is damaged; 2. The gear box is faulty; 3. The barrel friction shell.

solution:

1. Replace the bearing; 2. Repair the reducer; 3. Repair the adjusting wheel body.

3. Bearing temperature is too high

cause of issue:

1. Dirty grease; 2. Improper amount of grease; 3. Bearing damage (generally the first two reasons).

solution:

1. Replace the grease; 2. The amount of grease must be moderate, not too much or too little; 3. Replace the bearing.

4. Sanding and turning

cause of issue:

1. The speed of the spiral sand punching machine is too high; 2. The horizontal axis of the spiral disc is not fixed well.

solution:

1. Adjust the speed; 2. If the speed is adjusted in place and still rotates, fix the horizontal axis.

5. Frame vibration

cause of issue:

1. The bolts of the connecting frame are loose; 2. The bolts of the bearing seat are loose.

solution:

1. Tighten the bolts; 2. Check and tighten the bolts.

6. Transmission noise

cause of issue:

1. Insufficient gear lubrication; 2. Change in gear spacing.

solution:

1. Increase enough grease; (2. Adjust and tighten the base bolts of the reducer.

7. The discharge port is blocked

cause of issue:

This is the most likely problem in the operation of the sand washer. The main reason is that the sand in the sand washer is too fine, and the single feeding amount increases suddenly, resulting in the deposition of materials at the outlet.

solution:

First, stop feeding and open all outlets to avoid clogging. Wash the sand washer with clean water.

8. Gears are easily damaged

cause of issue:

1. The parallelism between the shaft of the sandblasting machine and the low speed shaft of the reducer does not meet the requirements.

solution:

1. Refuel at the prescribed time; 2. Adjust to meet the requirements.

9. Rotor core damage and deformation

cause of issue:

1. Excessive bearing wear or poor assembly causes the rotors to rub against each other, damaging the surface of the core and causing short circuits between silicon steel sheets; 2. The excessive force on the old winding causes the cogging to skew and spread outward; 3. The surface of the core Rust and moisture; 4. Loose connection between iron core and base.

solution:

1. Use burrs and other tools to deburr to eliminate short circuit of silicon steel sheet, apply insulating paint after cleaning, heating, and drying; 2. Use needle-nose pliers, wooden hammer and other tools to trim the edges and reset the teeth between the cracked silicon chips Steel plates with hard insulating materials such as green shell paper and rubber plates are added; 3. Sanded with sandpaper and coated with insulating paint after cleaning; 4. Tighten the original bolts. If the fixing screws fail, you can re-drill the bottom and tighten the base.

10. Reduced sand flushing or sand leakage

cause of issue:

1. The sand net is damaged; 2. The fixing bolts of the sand net fall off.

solution:

1. Repair or replace the sand net; 2. Fasten the bolts.