Silica sand processing plant equipment for glass manufacturer

February.20,2020

February.20,2020

The silica sand scrubber solves the problem that there is currently no special equipment for scrubbing quartz sand. The function of the equipment is to scrub the dust and oxidized impurities adhered to the surface of the silica sand; improve the purity of the silica sand material, and the scrubbing efficiency can reach more than 90%.

Use of silica sand

The strength of the processed sand core used in the cold core box method is significantly improved, and the amount of resin added can be reduced and the cost can be increased. This process is not only simple, but also low cost and easy to control, which significantly improves the quality of silica sand.

The flotation or magnetic separation of silica sand has an SIO2 content of more than 98%. It can be used for casting of cast iron, copper, aluminum and other non-ferrous metals. After processing of silica sand, the SIO2 content reaches the standards for glass and ceramics.

LZZG silica sand processing equipment

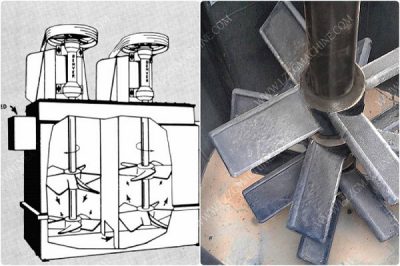

Silica sand scrubber frame, four scrubbing tanks 9 are set in the frame, and each scrubbing tank is equipped with a large and small impeller stirring device, which is characterized in that each stirring device is connected to its directly connected motor reducer 1, and the directly connected motor reducer 1 It is connected to the rack 3 mounted on the scrubber frame. Compared with the prior art, the utility model has the following advantages: the scrubber not only reduces the occupied space and volume, but also reduces noise and vibration. The scrubber can be used for high-concentration scrubbing methods, and the highest scrubbing concentration can be Up to 75%, the utility model greatly improves the efficiency of scrubbing the material and the scrubbing effect on the surface of the material, and the scrubbing qualification rate basically reaches 100%.

Silica sand beneficiation process

Commonly used beneficiation methods include ore washing, classification, scrubbing, gravity separation, magnetic separation, flotation, chemical beneficiation, etc. The beneficiation process shall be determined according to the nature of the ore and the requirements for the quality of the concentrate. Raw silica with pure chemical composition can be produced by wet or dry crushing, grinding, and grading. Ores with many impurity minerals or high product quality requirements require a combined process including several beneficiation methods, such as scrubbing-desliming-magnetic separation (or re-selection) -flotation processes. The principle flow of silica or silica sand beneficiation is shown in the figure. If the raw ore is silica, the ore should be crushed, screened, ground, and then entered into the sorting operation. When the raw ore is dry sand ore, water should be added to the pulp to remove coarse particles before entering the sorting operation. In wet sand ore, the coarse particles can be screened out after the coarse particles are sieved.

The silica sand processing equipment was exported to Europe, Australia, North America, South America, Southeast Asia, the Middle East, Central Asia, Africa, and other countries. Welcome to the inquiry and negotiate business!