Installation process of urea screening machine

February.27,2024

February.27,2024

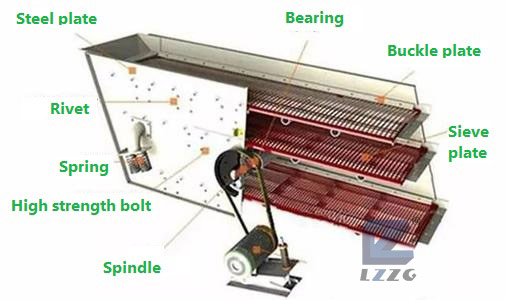

The urea screening machine should be carefully inspected before installation. If the urea screening machine is stacked for a long time, it is easy for the bearings to rust, the seals to age, and the parts to be damaged during transportation. When these problems are encountered, parts need to be replaced. In addition, in order to prevent the exciter from rusting, anti-rust oil is usually injected before leaving the factory and replaced with lubricating oil before official operation.

The installation steps of the urea screening machine are as follows:

1. Install supporting or hanging devices. During installation, the foundation should be leveled, and then the components should be installed in sequence according to the component diagram of the supporting or hanging device and the installation diagram of the screen. Before installing the spring, it should be selected according to the actual stiffness value marked on the end face.

2. Connect the screen box to the support or hanging device, and adjust the inclination according to the specified angle. For hanging screens, the inclination of the screen box and the level of the main axis of the screen box should be adjusted at the same time. Generally, the horizontal level is adjusted first to eliminate the deflection of the screen box, and then the longitudinal inclination of the screen box is adjusted. The stress of the vibration isolation spring should be uniform, and its stress can be judged by measuring the compression of the spring. Generally, the compression amount of the two sets of springs at the feeding end must be the same, and the same should be true for the two sets of springs at the discharging end. However, the compression amount of the springs at the discharging end and the feeding end can be slightly different.

3. Install the motor and V-belt. During installation, the foundation of the motor should be leveled, the level of the motor needs to be corrected, the center lines of the two pulleys corresponding to the grooves should coincide, the tension of the triangle belt should be moderate, and then the screen surface should be installed and fixed as required. And check the fixation of each connecting component of the screen (such as screen plate, vibrator, etc.) and the lubrication of the transmission part. The screen should be evenly tensioned to prevent localized vibrations. Check whether the wiring of the motor and control box is correct, and turn the transmission part by hand to check whether the movement is normal.

The last step is to check the inlet, discharge chute and lower hopper of the urea screening machine to see if there is any collision. If so, timely repairs are required.