7 troubleshooting tips for vibrating screen common problems

August.31,2019

August.31,2019

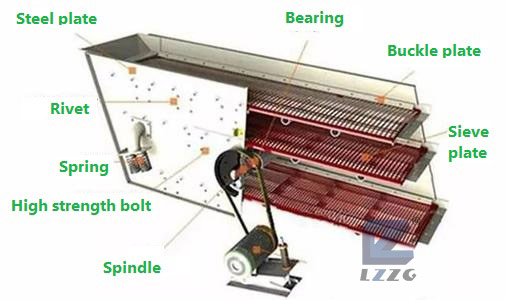

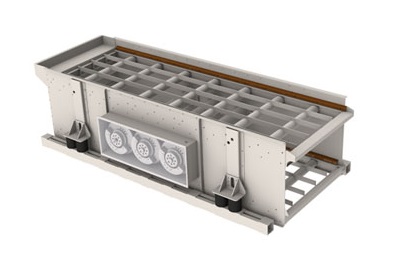

Mining vibrating screen used in metallurgy, mining, coal, building materials, electric power, chemical and other industries, especially in the metallurgical industry. It is the most widely used screening machine under the blast furnace tank, coking plant and concentrating plant.

In the machine work, due to various factors, it may cause various malfunctions in the vibrating screen. The following briefly introduces the causes of various faults and solutions.

Vibratory screen troubleshooting

1. The material flow on the vibrating screen is abnormal.

First, the rigidity of the screen box is insufficient, there is a critical frequency, the connecting bolt has been loosened, and even to the extent of full vibration, that is, tightening. Second, the horizontal level of the screen box is not accurately determined. From the support seat of the support foot spring or the spring itself, it is possible to change the spring or change the size of the support, and it is also possible that the screen mesh is damaged, as long as the screen is replaced. If the rigidity of the screen box is insufficient and the horizontal level is not accurately determined, the beam will be broken. If it is still running, the material will flow abnormally. It is also possible that the operation is improper, that is, the feedstock is extremely unbalanced.

2. The vibrating screen cannot be started or the amplitude is too small.

It should be checked whether there is any obstacle in the electrical, whether the vibration motor is damaged, or the components in the line are damaged, and the voltage is insufficient. These three aspects are no problem, and then the machine is checked and vibrated. Whether the material on the sieve surface is too much, if it is, it is removed. Whether the coupling bolt on the vibration exciter is detached or not, and the grease is thickened and agglomerated. At this time, the vibration exciter can be cleaned and repaired, and then the position of the eccentric shaft weighting block or the sub eccentric block can be appropriately adjusted.

3. The side plate of the vibrating screen is cracked, the beam is broken, and the structural parts are damaged.

4. The vibrating screen rotates slowly and the bearing heats up.

This situation indicates that the usual maintenance has not kept up, the bearing lacks grease, and if it is newly added grease, it is the quality problem of the grease or it is too full, and the inferior oil makes it The bearing blocks the labyrinth seal jam, so the quality of the grease is quite important.

5. The quality of the vibrating screen is poor.

The reason is that there are many responsibilities for improper operation. The mesh may be clogged, the fine particles in the sifting material increase and the moisture increases, so that the upper layer of the screen is too thick, the feeding is uneven and so on. It is possible that the two sides of the screen are not tightly pulled. If the shaft is eccentrically vibrated, the belt may be weak in the dragging, the belt is too loose, and the mechanical problem is solved, and the reverse rotation may be performed for a period of time to improve the screening quality.

6. The noise of the circular vibrating screen is too large

Which may be damage to the bearing, loose bolts, broken beam, and spring damage. In addition to the bolts can be tightened, the other three conditions need to be replaced.

7. shaker assembly is incorrect

For example, the double-box exciter has different angles of interest when the vibration vibrators of the two exciters. The purpose of causing the vibration marks on both sides of the sieve plate is different. When adjusting, the screen box can be leveled first, and the center of the vibration input shaft of the exciter is slightly higher than the center of the flange of the transmission assembly, and the gap between the two flanges is suitable, and then the coaxial is adjusted to meet the requirements.