Equipment for screening vegetation, fine soil, and stones

December.25,2025

December.25,2025

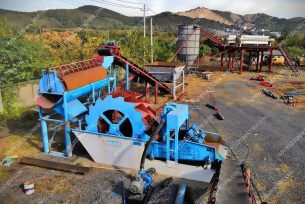

Soil screening machines are construction machinery used to separate impurities such as stones and decaying leaves from soil and to classify them by particle size. They are mainly used in mining, coal, building materials, agriculture, and environmental monitoring. According to their structure and motion, they can be divided into linear vibrating screens, circular vibrating screens, drum screens, and gyratory screens. Linear vibrating screens have a processing capacity of 0.12-20 t/h and are suitable for screening fine materials; circular vibrating screens have a processing capacity of 75-1500 t/h and are suitable for screening sticky materials and large particles.

The equipment adopts a vertical drum design, equipped with moving and adjustable fixed blades to improve crushing quality. An eccentric connecting rod mechanism is used to set a quick-return characteristic and a 2.5° downward deflection angle to improve screening efficiency. The vibrating screen can be adapted to 20-200 mesh screens. Screening accuracy is affected by the vibration frequency adjustment. Some models are equipped with diesel engines or IoT sensors to adapt to all-weather operation. During operation, the soil moisture content must be controlled below 20%. Adjust the number of fixed blade layers to suit different soil types and remove hard objects such as metal blocks to prevent equipment malfunction.

Precautions:

Mature soil from vegetable gardens and paddy fields is best, with a suitable moisture content of 20%. Soil with excessively high moisture content should be turned over and dried before use. Remove metal blocks, stones, bricks, tree roots, and other debris from the soil to avoid damaging the blades and machine.

Adjust the number of fixed blade layers inside the drum according to different soil types and moisture contents. Use two fixed blade layers for harder soil or lower moisture content; use one fixed blade layer for clay soil or moderate moisture content; use zero fixed blade layers for sandy soil or higher moisture content.