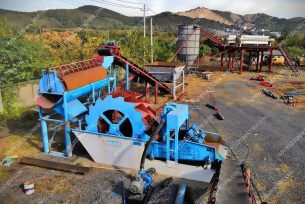

Drum wash plant for aggregate, coal washing and screening

August.14,2019

August.14,2019

Cage drum screen is another new generation of screening equipment after plane vibrating screen and cantilever vibrating screen. It is widely used for screening various solid fuels with a particle size below 400mm. Cage drum screen has many advantages such as wide adaptability of coal type, simple coal feeding mode, high screening efficiency, large screen component, low energy consumption, low noise, strong sealing performance, long service life, small maintenance, and convenient maintenance. Its screening capacity is 150t / h – 420t / h, or even higher.

How the device works

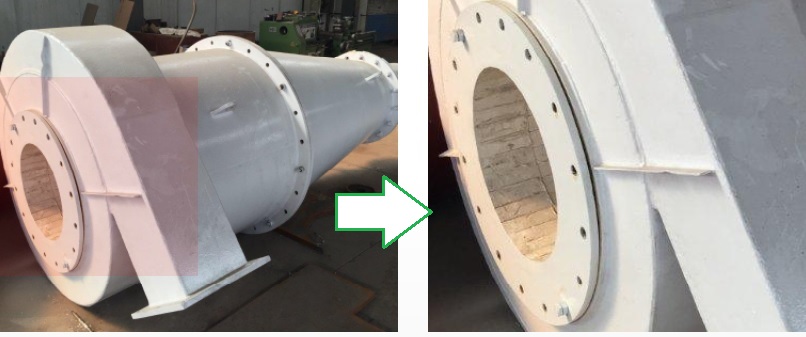

The main structure of the cage drum screen is a screening cylinder, which is a screen composed of a plurality of annular flat steels. The whole is inclined with the ground plane, and the outside is sealed by a sealing spacer to prevent environmental pollution. Through the variable speed deceleration system, the screening cylinder is rotated at a certain rotation speed, and the coal is separated from the top to the bottom through the screening cylinder, and the fine material is discharged from the lower part of the front end of the screening cylinder, and the coarse material is taken from the lower end of the screening cylinder. The cage drum screen is provided with a comb-type cleaning mechanism. During the coal-sieving screening process, the relative movement of the comb-type cleaning mechanism and the screening cylinder is achieved to achieve an uninterrupted cleaning effect on the sieve body, so that the screening cylinder is entirely It is always clean during work, non-stick, non-blocking, and does not affect screening efficiency.

Equipment performance characteristics

1. Wide adaptability of coal types

Cage drum screen is widely used in various types of coal-fired screening. Whether it is inferior coal, coal slime or bituminous coal or anthracite, it can be smoothly screened regardless of whether the coal is wet or dirty.

2, the way to enter the coal is simple and diverse

The cage drum screen coal inlet developed by our company can be designed according to the actual situation of the site. No matter whether it is a belt, funnel or other coal feeding method, it can smoothly enter the coal without special measures.

3, high screening efficiency

4, the screen component is large, easy to enlarge

5, its own energy consumption is small

Preparation before commissioning

1. After the components of the drum screen are installed, after the inspection is passed, the test run can be carried out. Before the test run, the components should be inspected in detail as shown in the drawings. The fasteners are secure and there are obstacles around the screen that interfere with the operation of the drum screen;

2. Check that each bearing seat and gearbox should be well lubricated, and the oil level of the gearbox should be appropriate;

3. The power connector should be firm and reliable, with good insulation and correct grounding.

Since the product was put on the market, it has been favored by customers. Because of its unique performance characteristics, it can completely solve the problems that other sieve types can’t solve. If the coal-fired water reaches 10% or more, other sieve types will not work properly, and the drum screen developed by our company can also be screened normally, and there will be no sticking, blocking and overloading.