Advantages of Using Ball Mills for Sand Making

November.24,2025

November.24,2025

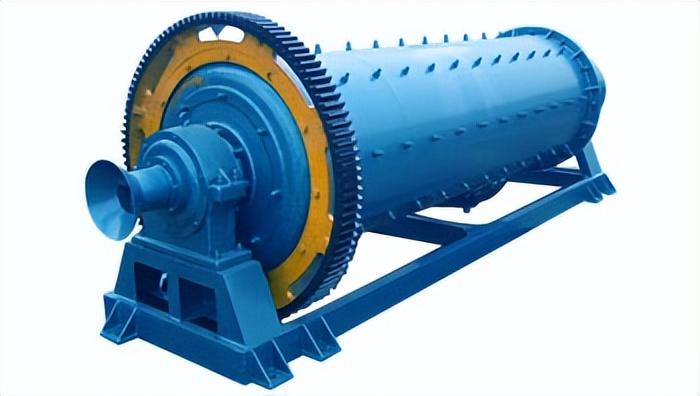

Ball mills are not only commonly used mineral processing equipment, but also high-performance artificial sand making equipment. These machines come in various types and models to meet the production needs of different users. Based on the grinding media, they can be divided into three main series: ball mills, rod mills, and ceramic ball mills.

Sand produced by ball mills typically has controllable particle size, full particle shape, and good finished product quality, making it very popular with market users. Its feed particle size is ≤20mm, and the output is 45-100t/h.

Many small sand making plants use dry ball mills as sand making machines.

The advantages of dry ball mills for sand making:

1. Good finished product quality: The feed and discharge of ball mills are adjustable, and the output particle size is generally between 0.074-0.45mm, making it perfectly suitable for use as a sand making machine. The finished product has uniform, full particle shape and strong cohesion. By using different gradations of grinding media, the phenomenon of over-grinding can be reduced, greatly increasing the output.

2. Excellent Environmental Performance: The ball mill’s cylinder has a good sealing effect, resulting in minimal dust leakage during daily operation and low operating noise (≤70 decibels), contributing significantly to environmental protection.

3. Low Operating Costs: Dry ball mills have no lubricated parts internally, leading to a very low failure rate. The cylinder does not require cooling, resulting in a long service life, stable performance, and the ability to operate continuously for extended periods.

Another advantage of using ball mills for sand making is their significantly lower price compared to professional sand making machines, although output is lower. This makes them particularly suitable for small or family-run sand making plants.

Differences between Ball Mill Sand Making and Professional Sand Making Machines: Ball mills offer high efficiency, stable performance, beautiful finished product particle shape, high gradation, uniform particle size, high quality, good appearance, and excellent sand making effect, making them very popular in the market. Furthermore, the particle size of the sand produced can be adjusted, producing coarse, medium, fine, and extra-fine sand, fully meeting the high-standard construction sand requirements of users. Ball mills and sand making machines have different feed particle sizes. The feed particle size of a sand making machine is ≤60mm, and its output is 60-300t/h.