Gravity beneficiation (referred to as gravity separation) is based on the density of various minerals (usually called specific gravity), so the gravity, fluid power and other mechanical forces experienced in the moving medium are different, so as to realize the process of separating the ore particles by density. . Mineral particles and shapes will affect the accuracy of sorting by density. Due to the difference in density of various mixed mineral particles, the sedimentation speed and the degree of movement in the moving media (such as water, heavy media with a density greater than water, air, etc.) are different, so as to achieve the separation of minerals and all re-elections. The process is based on the sedimentation law of mineral particles in the selected medium.

The grain size of chromite ore is generally medium and fine, so the chromite ore washing machine | chromite ore washing machine | chrome ore washing machine also mostly includes crushers, rod mills, etc., chromite ore heavy separation The determination of the equipment needs to be based on the specific particle size of the chromite ore. If the particle size of the cloth is relatively coarse, most of the monomer can be dissociated after grinding with a rod mill, and the rod mill-jigging process is used, such as inlaid If the cloth particle size is finer, a ball mill is required to grind the ore. After the ore product reaches the monomer dissociation, it enters the strong magnetic separation process or the flotation process.

Crushing process: In the chromite ore beneficiation process, the crushing process uses two-stage jaw crushing to crush the raw ore to less than 30mm, and then transport it to the next silo through a conveyor.

Grinding process: Rod mill is used in the grinding process to grind ore. Because the particle size of the general chromite ore is slightly coarser, the monomer can be dissociated by simple rod mill grinding. At the same time, the rod mill has high output and product particle size. Uniform and adjustable, it is an ideal chromite grinding equipment. A vibrating feeder is installed under the silo, and the crushed products are evenly fed into the rod mill for grinding operations.

Gravity separation process: It has been reduced to that the grain size of chromite ore is generally relatively coarse. The rod mill is used for grinding to achieve monomer dissociation and then enters the gravity separation process. The equipment suitable for chromite gravity separation is mainly skipped. The jigging machine, shaker, and jigging machine have a large processing capacity and have a significant effect on the roughing of chromite ore. Therefore, the trapezoidal jig with large processing capacity and high recovery rate is used in the roughing process of gravity separation. Since the jigging machine has no obvious recovery effect on the fine-grained powdered ore, a shaker can be set up after the jigging machine tailings for sweeping, and the lost ferrochrome can be recovered to improve the recovery rate of the entire process flow.

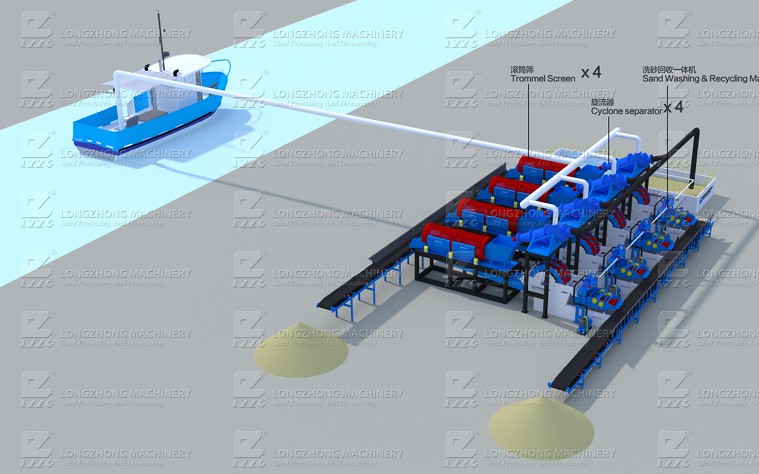

Equipment for extracting sand and gravel from river silt

Modular Construction Waste Processing Plant

Jigging machines for tungsten tin and gold ore dressing

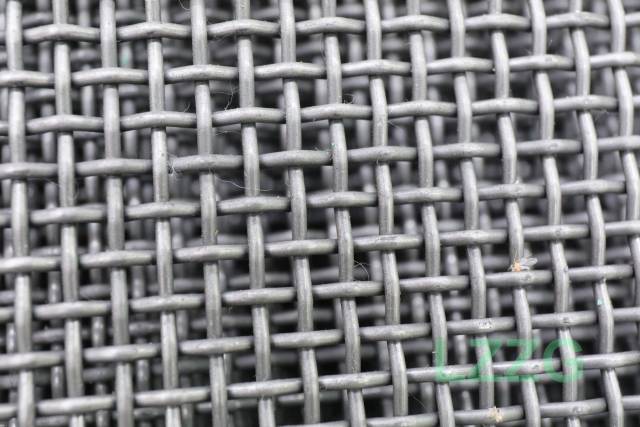

Mining wear-resistant manganese steel screen woven ore classification screen