Filter press for sand washing sludge treatment

Filter press produce mud cake of 25% moisture content

The filter press is a fully-automated system for sludge water treatment for sand washing plant, concrete manufacturing plant, industry wastewater. does not require operator assistance and in most cases, no additional chemicals are needed. The sludge is sent to every sealed filter chamber by the feeding pump with pressure, going into filter plates and filter cloths. The clean water will be filtered out from the filter plate water outlet by the filter cloth, but the solid is kept in the chambers to separate solid and liquid, finally, we will get the slurry cake to contain 25% water.

Working principle

When the Filter press is operated, the sludge is discharged from the feed inlet into the filter cylinder and is moved to the discharge port by the push of the spiral shaft rotary vane. The pitch is gradually reduced, so the pressure of the sludge is also increased, and the pressure difference is started to be dehydrated, and the water is from the fixed ring and the activity.

The annular piece is filtered out of the gap, and the filter press depends on the self-cleaning function between the fixed plate and the movable plate, and the clearance between the filter and the filter is prevented from being blocked. After fully dehydrated, the discharge is discharged from the discharge port under the action of the propeller shaft.

Product Features

1. Providing efficient cleaning support to sludge accumulated in wastewater.

2. The machine works on the principle of pressure feeding that provides for optimum output support.

3. Supports a reduction in moisture content of sludge significantly.

4. Working as the solid-liquid separation device, the system can also be custom tuned as per the specific work process needs of customers.

5.Suitable for dewatering low and high concentrated sludge.

filter press mud cake

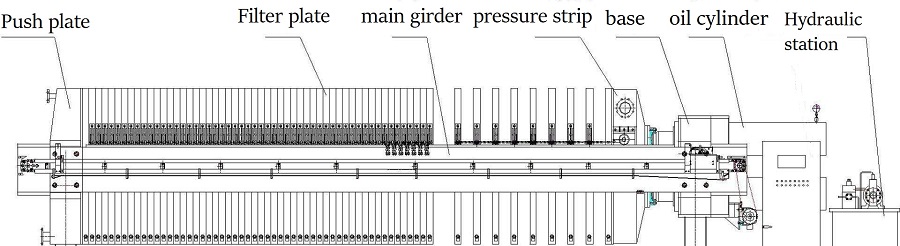

The structure of filter press

The plate and frame filter press is the first machine used in chemical dehydration. Although the plate and frame filter press generally has an intermittent operation, the large investment in infrastructure equipment, and low filtration capacity, it has large filtration driving force, the high solid content of filter cake, clear filtrate, high solid recovery rate, and conditioning medicine. The advantages of low consumption and so on are still widely used in some small sewage plants.

Rack section

The frame part is the main body of the machine to support the filter mechanism and connect other components. It is mainly composed of a thrust plate, a pressing plate, a cylinder block and the main beam.

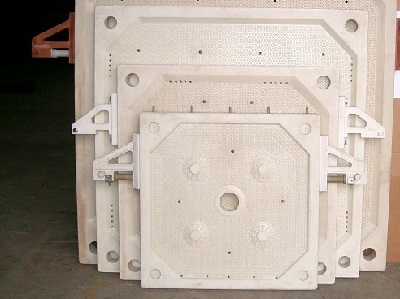

Filter section

The filtering part is composed of a filter plate arranged on the main beam in a certain order, a filter cloth sandwiched between the filter plates and a diaphragm filter plate.

Pull plate part

1. The automatic pull plate part

The automatic pull plate portion is composed of a hydraulic motor, a robot, a transmission mechanism, and a suspension device.

2. The manual pull plate part

Manually pull the plate to discharge the material.

Hydraulic part

A hydraulic part is a power unit that drives the pressing plate to press or loosen the filter plate and is equipped with a plunger pump and various control valves.

Electronic control part

The electronic control part is the control center of the entire system.

Filter board selection should pay attention to

1. Corrosion-resistant rubber coated and reinforced thick steel plate material molding (SRRM) so that the filter plate can be long-lasting and non-deformable. Many manufacturers purchase the commercially available rubber-coated steel plate, which is not easy to deform.

2. PP polypropylene rafts should have sufficient support for the increase in strength of Stay Bosses, insufficient support or incorrect alignment, and reduced reinforcement.

Technical parameters

| Model | Capacity (t/h) | Filter Area (m²) | Filter Plate (mm) | Plate Number (block) | Filter Pressure (mpa) | Power (kw) | Weight (kg) | Overall Size (mm) |

| G60-100 | 1-1.5 | 60 | 1000*1000*65 | 37 | 0.6-0.8 | 3 | 4800 | 5120*1450*1360 |

| G100-100 | 2-3 | 100 | 1000*1000*65 | 61 | 0.6-0.8 | 3 | 6630 | 6730*1450*1360 |

| G150-125 | 3-5 | 150 | 1250*1250*65 | 57 | 0.6-0.8 | 4 | 7950 | 7560*1840*1620 |

| G200-125 | 4-6 | 200 | 1250*1250*70 | 76 | 0.6-0.8 | 4 | 10800 | 9240*2050*1680 |

| G250-125 | 5-7 | 250 | 1250*1250*70 | 94 | 0.6-0.8 | 4 | 12060 | 10580*2050*1680 |

| G350-150 | 6-8 | 350 | 1500*1500*75 | 89 | 0.6-0.8 | 5.5 | 20880 | 10920*2500*1920 |

| G400-150 | 9-11 | 400 | 1500*1500*75 | 102 | 0.6-0.8 | 5.5 | 23480 | 11930*2500*1920 |

| G500-150 | 11-12 | 500 | 1500*1500*75 | 127 | 0.6-0.8 | 5.5 | 24880 | 13830*2500*1920 |