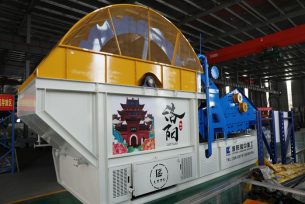

High-efficiency gravel scrubbing and dehydration all-in-one machine

May.25,2023

May.25,2023

GX series high-efficiency scrubbing all-in-one machine is a new type of sand washing equipment developed by Longzhong Heavy Industry for materials with high clay content. It can complete 50-250 tons of sand washing and recycling per hour. Widely used in quartz sand, ore sand, mountain sand, especially suitable for scrubbing and recycling materials with clay and clay blocks, hard ores, aggregates and other materials.

Gravel cleaning steps

1. The mixed material first enters the scrubbing machine for full scrubbing, and then goes through the impeller separator for cleaning and water control to achieve the effect of mud and sand separation.

2. The wheel bucket material enters the coarse sand dehydration area of the dewatering screen for dehydration, and the overflow dirty water is concentrated by gravity classification of the separator group, and then discharged into the inlet of the impeller separator through the bottom flow port for secondary cleaning.

3. The mixture passing through the coarse sand dehydration zone is then concentrated by gravity classification of the second separator group and discharged into the fine sand dewatering zone of the dewatering screen through the bottom outlet. So as to achieve efficient sand washing.

The uniqueness of the high-efficiency sand and gravel scrubbing machine

1. The structure design is compact and reasonable. Combining the traditional scrubbing machine with the wheel type sand washing machine can make the material and the material fully rub to remove the surface attachment.

2. There is a maintenance platform, which is convenient for viewing the data of the filter press table, replacing the screen, the drip port of the cyclone, etc., and it is convenient for repair and maintenance. At the same time, you can also observe the working conditions and scenes here, so as to understand the production situation.

3. The slurry pump adopts slideway installation method, which reduces the occupied area and is easy to install and maintain.