Complete oil fracturing sand production line

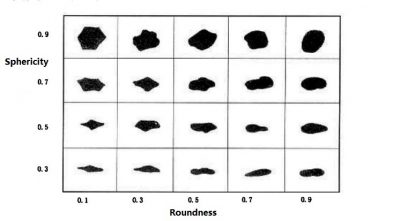

Oil fracturing sand has high compressive strength and is mainly used for downhole support in oil fields to increase oil and natural gas production, and is an environmentally friendly product. The product has the advantages of high compressive strength, low density, good sphericity, high smoothness and strong flow conductivity.

The specifications of petroleum fracturing sand products are: 20-40 mesh, 40-70 mesh, 70-140 mesh. In the field of petroleum, fracturing refers to a method of using hydraulic action to form cracks in oil and gas layers during the process of oil or gas production, also known as hydraulic fracturing.

The overall fracturing sand production line is divided into five working stages, namely the raw material mining stage, the raw material drying and pre-screening stage, the raw material washing stage, and the concentrate drying stage. It can solve the problems of fracturing sand classification, washing, tail water purification, solid waste dry discharge, etc. The finished product can achieve round sand particle size and higher compression value. The entire production line has large output, high efficiency, stable operation, and equipment can be configured according to customer conditions.

Working principle

The raw sand of fracturing sand enters the silo for storage, and is sent to the vibrating screen or probability screen for preliminary screening through the belt conveyor. <20 meshes are magnetically separated by a magnetic separator, and then enter the scrubbing machine. When the materials pass through, they are fully stirred and washed. After scrubbing off the mud, they enter the sand washing and recycling integrated machine. , which can remove the impurities covering the surface of the material. After cleaning, the coarse-grained material is sent to the dewatering screen by the sand fishing wheel for dehydration. The granular material after sand washing is dried by the dryer, and the material to be dried slips into the cylinder from the feeding box and the feeding material, so as to achieve the purpose of drying. The dried materials are screened by a swing screen, and the screening accuracy can reach 90-95%. The qualified fracturing sand is packaged and shipped out.

The tail water treated by the separator of the integrated sand washing machine enters the sewage transfer tank, and then the tail water is pumped from the sewage tank into the trihydrogen purification body by the pump for mud-water separation operation. The concentrated mud is pumped into the plate and frame filter press through the bottom of the filter tank to achieve dry stacking. After pressure filtration, the clean water enters the clean water tank to realize the recycling of clean water.

Product Features

1. Advanced equipment: The fracturing sand production line has the characteristics of high production efficiency, fully automatic control, and no dust pollution.

2. Automatic production: The dust removal system of the oil fracturing sand production line adopts the design of the automatic control system, and the dust removal effect reaches the standard.

3. Save investment: The production line adopts advanced technology, low investment, high output, low pollution, and the principle of recycling, reducing and harmless waste materials.

4. Strong pertinence: For oil fracturing sand research and development production lines, equipment can be configured according to customer conditions.

5. The whole production line process realizes material washing, tail water purification, solid waste dry discharge, and can achieve zero discharge.