5 indicators of high quality fracturing quartz sand

June.03,2020

June.03,2020

In the petroleum industry, fracturing quartz sand does not really value the content of silica. There is another set of evaluation criteria for good fracturing sand. If your fracturing sand can achieve the following 5 points, then congratulations, you and your fracturing sand will be warmly welcomed by the oil industry.

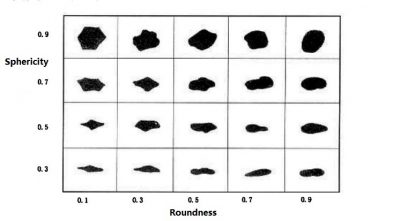

1. sphericity and roundness

Sphericity, well understood, refers to how close the fracturing proppant (ie, quartz sand) is to a spherical shape.

The roundness is interpreted as the degree to which the cross-section of the workpiece is close to the theoretical circle.

In the eyes of unfamiliar people, the concept of roundness is a bit abstract. In fact, roundness can be understood as “roundness” in simple terms. The more sharp and sharp the particles are, the worse the roundness is;

The sphericity and roundness of natural quartz sand should not be less than 0.6. In actual testing, the proppant sphericity and roundness plates are used to test the proppant sphericity and roundness, see the figure below.

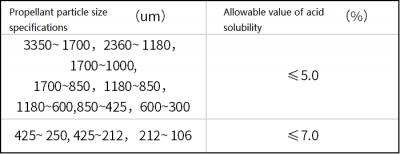

2. Acid solubility

Acid solubility refers to the percentage of the mass of a certain mass of proppant dissolved by acid and the mass of the total proppant under the specified acid solution and reaction conditions.

Acid resistance is an important indicator of fracturing proppants. Propants with good acid resistance can work longer in acid rock formations and maintain good conductivity.

The allowable acid solubility values for proppants of various particle size specifications are shown in the figure below. It is worth noting that the acid solubility index of quartz sand and ceramsite proppant are the same.

3. Turbidity

The turbidity of the proppant is the degree of turbidity of the liquid after adding a certain amount of proppant to the specified volume of distilled water and shaking and placing it for a certain period of time. The unit is FTU.

The turbidity mainly characterizes the surface finish of the proppant, reflecting the number and size of particles on the surface. According to regulations, the turbidity of quartz sand for fracturing should not be higher than 100FTU.

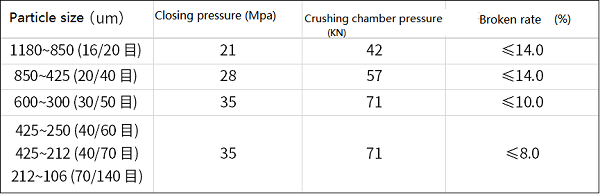

4. Anti-crushing ability

For a certain amount of quartz sand proppant, the crushing rate determined by the pressure test under the rated pressure characterizes the proppant’s resistance to crushing. The main factors affecting the crushing rate are the roundness, sphericity, surface finish, and microstructure of the quartz sand proppant.

The fracture rate of quartz sand proppant affects the fracture conductivity. The crushing capacity test of natural quartz sand proppant should use the crushing chamber of the specified size range, see the following figure.

5. Volume density and apparent density

The bulk density of the quartz sand proppant is the mass of proppant per unit volume (unit g/cm3) and reflects the overall density of the proppant stack. The main factors affecting the bulk density are the apparent density, roundness, sphericity, surface finish, etc. of the sample.

The apparent density of the proppant is the mass of proppant per unit particle volume (unit g/cm3). The difference from volume density is that the volume when calculating apparent density does not include the void volume between particles. The main factors affecting the apparent density of the proppant are the phase composition, structure and porosity of the sample.

For different densities of fracturing proppants, different test indexes are used. In summary, the quartz sand for fracturing has the following requirements: uniform particle size, low density; high strength, low crushing rate; high roundness and sphericity; low impurity content; wide source and low price.