VSI9526 Vertical shaft impact crusher for Sand Gravel production

December.11,2019

December.11,2019

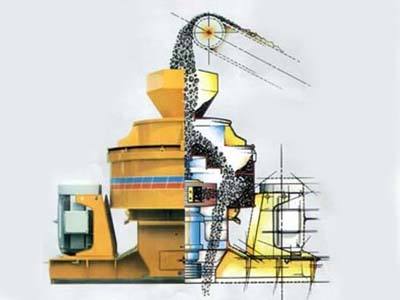

Impact sand gravel making machine instruction

Vsi impact crusher is new type sand making the machine, has better comprehensive performance than the rod mill sand making machine, the straight-through impact sand making machine, and the cone crusher and soft hammer crusher. It has the characteristics of stable and reliable work, convenient maintenance and high sand production rate. The equipment is suitable for stone shaping, production mechanism sand, sand making field, high-grade highway, railway, water conservancy, construction, cement, refractory, metallurgy, glass sand, and other industries.

Structure

VSI Sand Making Machine Features

1. Special light oil lubrication system ensures the temperature to be within 25 ºC.

2. Brand new automatic protection device provides the machine with vibrating, oil filtering and warning system.

3. A new type oil filtering device ensures the bearings and other transmission devices not being abraded and prolong their service time.

4. Optimized design of wearable materials has prolonged the service time of the machine by 40%, so the cost is lowered by more than 40%.

5. Better design of the impellers reduces the resistance of materials; high lightens passing through quantity of materials and crushing ratio, so the efficiency is raised by 30%-60% compared to traditional machines.

6. The hydraulic system allows automatic uncovering, which reduces labor intense and makes maintenance easier.

7. The mainframe adopts new techniques, which strengthens the machine structure and tenacity, and ensures stable performance. The quality of the machines is to lift to a higher level.

Technical parameters

| Model | Feed at center&sides | Feed at center | Soft Material | Hard Material | REV (r/min) | Power (kw) | Motor Model | Machine Size (mm) |

| Capacity(t/h) | Max. Feeding(mm) | |||||||

| VSI7611 | 120-180 | 60-90 | 35 | 30 | 1700-1890 | 4-55×2 | Y250M-4/55 | 4100×2250×2258 |

| VSI8518 | 200-260 | 100-130 | 40 | 35 | 1520-1690 | 4-90×2 | Y280M-4/90 | 4140×2280×2425 |

| VSI9526 | 300-380 | 150-190 | 45 | 40 | 1360-1510 | 4-132×2 | Y315M-4/132 | 4560×2450×2780 |

| VSI1140 | 450-520 | 225-260 | 50 | 45 | 1180-1310 | 4-200×2 | Y315L2-4/200 | 4560×2450×2780 |