Spiral sand washing machine with dewatering screen for sale in Korea

June.29,2019

June.29,2019

The spiral sand washing machine is a multifunctional washing machine that combines the functions of sand washing, sand and stone dehydration, and recycling. It is designed and developed by our company for the stone powder and the material containing high mud content in the sand and gravel washing industry. The structure of the equipment is reasonable, and the tailings dry sieve is used together with the double-screw sand washing machine to set up more than 300 tons per hour. It effectively solves the shortcomings of a large amount of fine sand loss and the unclean cleaning of the traditional spiral sand washing machine. Through the washing and selection of the equipment, the finished sand grading can be made more reasonable, and the customer’s quality requirements for the sand content can be satisfied.

spiral sand washing machine parameter

[Feed size]: ≤10mm

[Processing amount]: 30-240t/h

[Applicable materials]: River pebble, granite, limestone, basalt stone, coal gangue, weathered sand, river sand, yellow sand, and many other materials.

[Scope of application]: This equipment has been widely used in various industries such as sand mining yards, mines, construction sites, highways, road and bridge construction, concrete mixing stations, water conservancy and hydropower, and chemical industry.

[Applicable production line]: River pebble sand, granite chopped sand, limestone crushing mill, basalt crushing sand, coal gangue crushing sand and other material production lines.

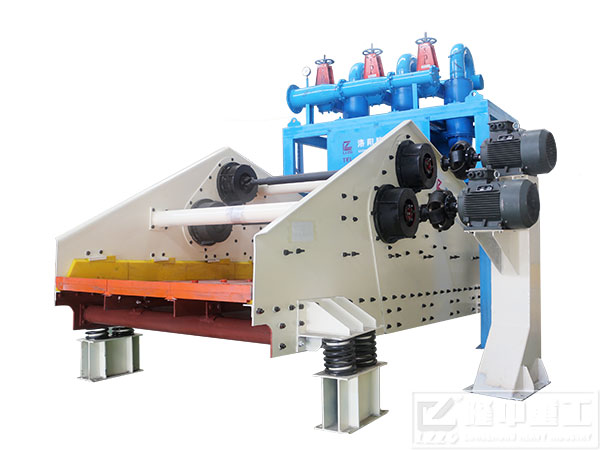

Sand and stone dewatering screen

[Feed size]: ≤10mm

[Processing capacity]: 120-480 tons / hour

[Screen area]: can be customized according to the output, the amount of water handled, etc.

[Usage scenario]: It is mainly used for dehydration of metal tailings such as iron ore, copper ore, gold ore and aluminum ore.

[Scope of application]: This equipment has been widely used in various industries such as sand mining yards, mines, construction sites, highways, road and bridge construction, concrete mixing stations, water conservancy and hydropower, and chemical industry.